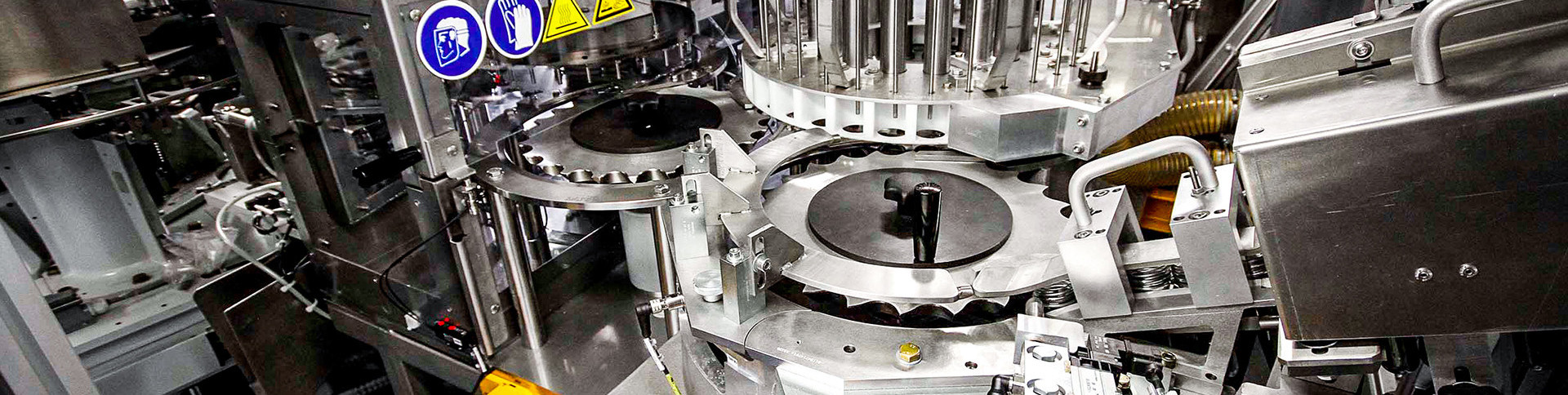

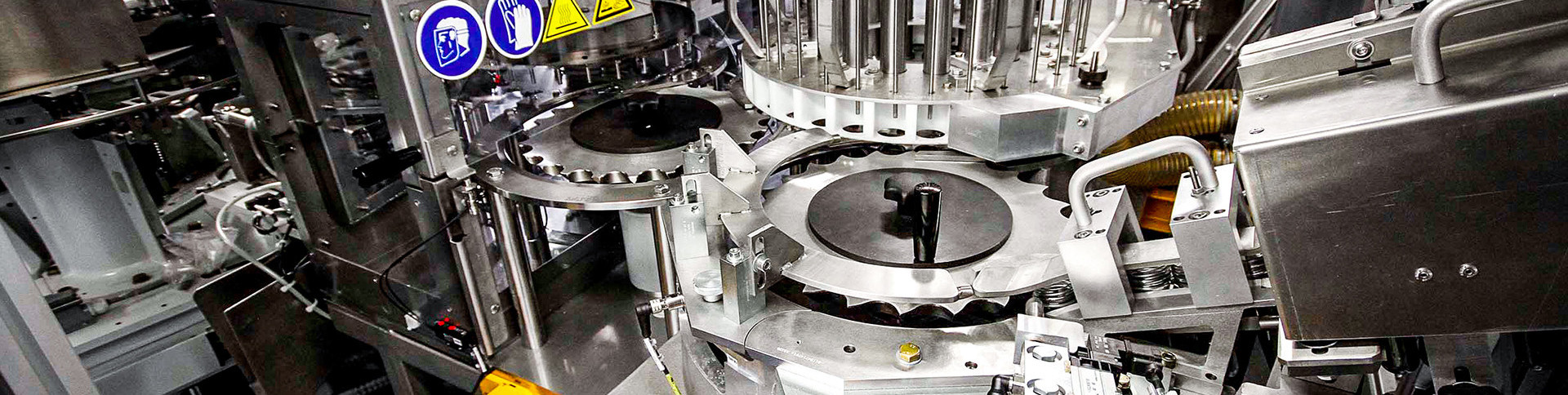

Sidel EvoBLOW Aseptic is equipped with the unique, proven, dry-preform sterilisation solution, Predis™, built on a long history with sensitive products, impressive aseptic expertise and innovative PET technology that unmatched in the liquid-packaging industry.

The preform is sterilised with hydrogen peroxide (H2O2) before being heated in the oven, which activates the H2O2 from the existing preform-heating stage and achieves a high level of decontamination. This results in a reduced risk of peroxide residue remaining within the preform. The same dry sterilisation technology is applied for caps with Capdis™.

Sidel EvoBLOW Aseptic is supplied mainly in Combi configuration including preform sterilisation, blowing, filling and capping. This technology is used by many major beverage and dairy companies and Sidel Aseptic Combi Predis™ is the beverage industry standard for aseptically producing PET packaging for teas, juices, nectars, isotonics and liquid dairy products (such as UHT milk or soy milk).

The Sidel Aseptic Combi Predis offers the beverage industry:

The Sidel Aseptic Combi Predis offers total flexibility with maximum uptime. Many beverage recipes can be produced in PET bottles, in various bottle shapes and sizes, without compromising on production rates or lightweighting possibilities.

Sidel Aseptic Combi Predis is:

Sidel Aseptic Combi Predis also offers beverage producers:

Compared to traditional aseptic filling systems, the new Sidel Aseptic Combi Predis offers cost-efficiency and an optimal environmental footprint:

The Sidel Aseptic Combi Predis is designed to ensure food safety, product integrity and a longer shelf life for sensitive products without using preservatives. It is also simple to operate and maintain.

The Sidel Aseptic Combi Predis offers the longest aseptic bottling uptime available on the beverage market.

The low output Combi Predis Capdis leverages Sidel unrivalled aseptic dry-preform and cap technology for those who need flexible aseptic PET packaging production at lower speed for small batches prior to a wide-scale roll-out, small volumes for regional markets or niche markets or for dairy applications.

Did you know that you can safely produce any kind of high or low acidity beverage in aseptic conditions with both cost-effective and environmental benefits? You can simply achieve this while ensuring food safety with the Sidel integrated blow-fill-cap solution including dry preform decontamination: the Sidel Aseptic Combi Predis™. It ensures 100% sterilisation of your packaging using no water and almost no chemicals. It is designed to protect the integrity and safety of your products while generating cost savings for your business.

Always by your side on every step of the way to build, maintain and improve your line performance