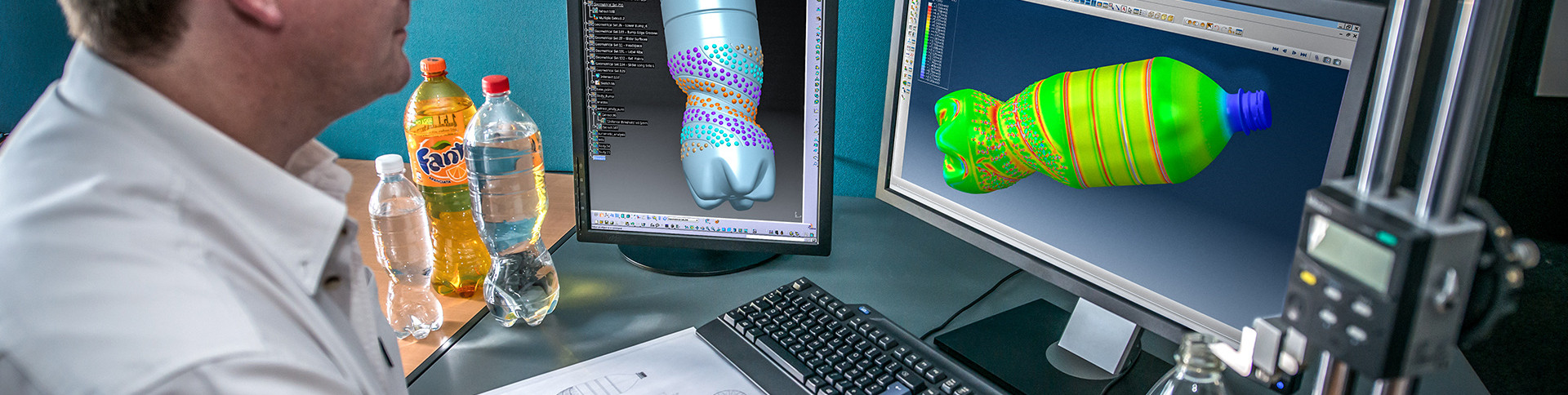

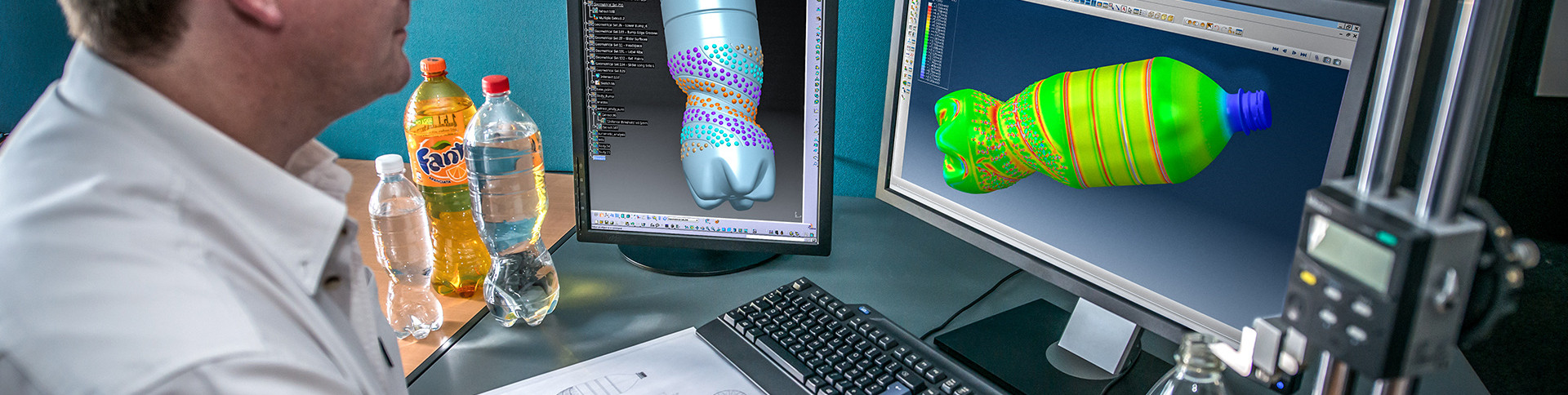

Consumers look for interesting bottle shapes and format sizes that fit their lifestyles. And based on your insights, specifications, supply chain conditions and product goals, we can help you design a package in line with your brand. A bottle that is ergonomic, durable and unique.

Our capabilities include:

Why your packaging should be made of PET

PET offers great freedom of shape, which can help create a standout brand. It can also be moulded into single-serve, multi-serve or extended-family formats. Consumers like the convenience, re-sealability and recyclability of PET. Meanwhile, you will appreciate the environmental and cost-saving benefits it delivers.

Preforms: Cut an extra 15% off the weight

Sidel has redesigned the standard preform with a 26/22 neck finish in order to cut an extra 15% off the weight. With lighter preforms and shorter necks, we can help you save costs while maintaining bottle performance and ensuring a strong consumer experience.