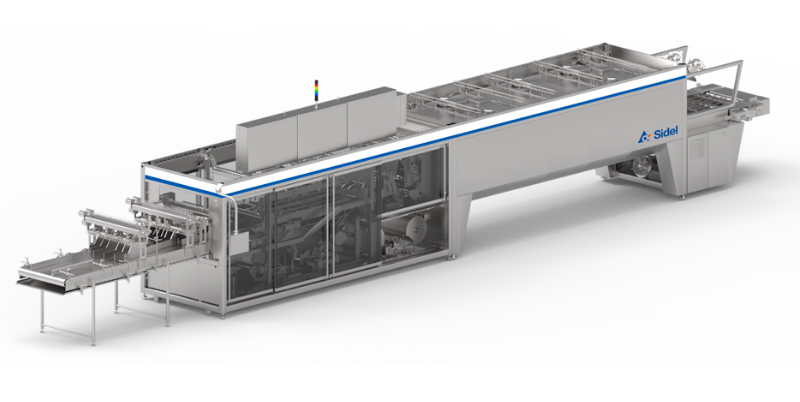

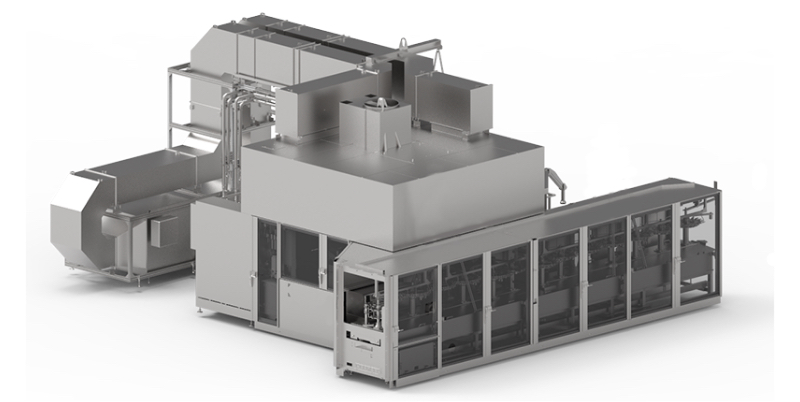

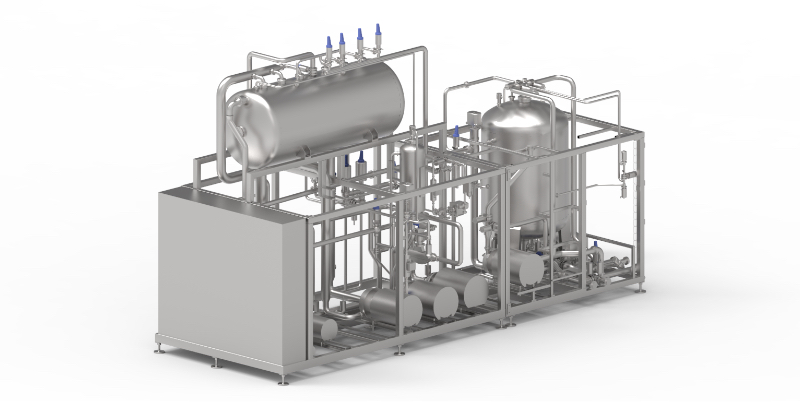

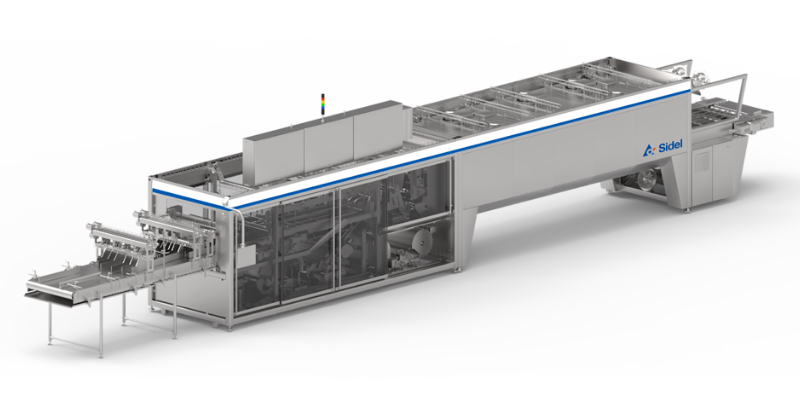

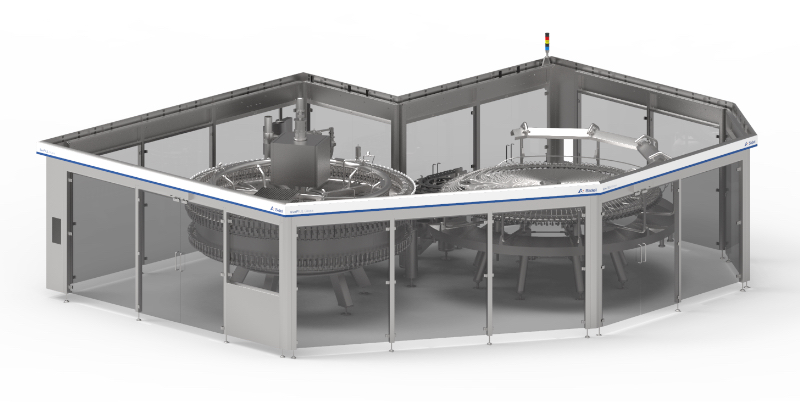

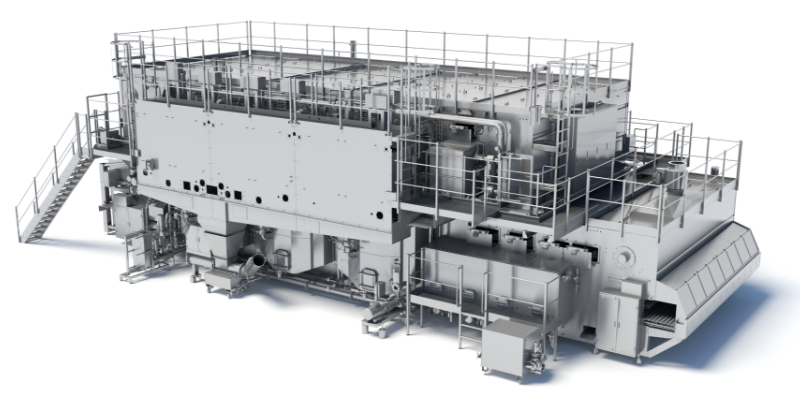

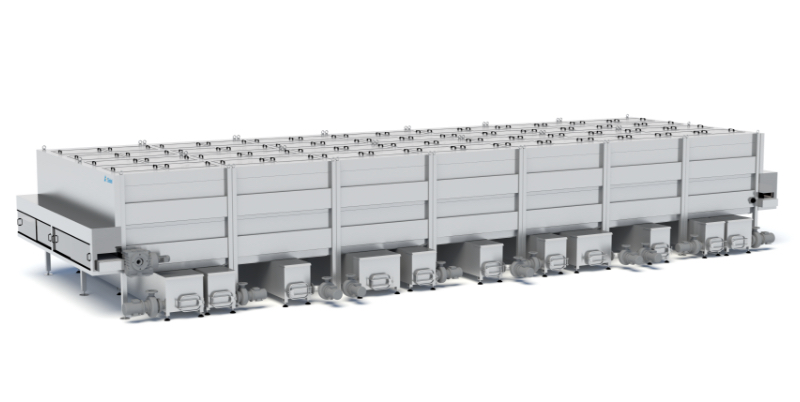

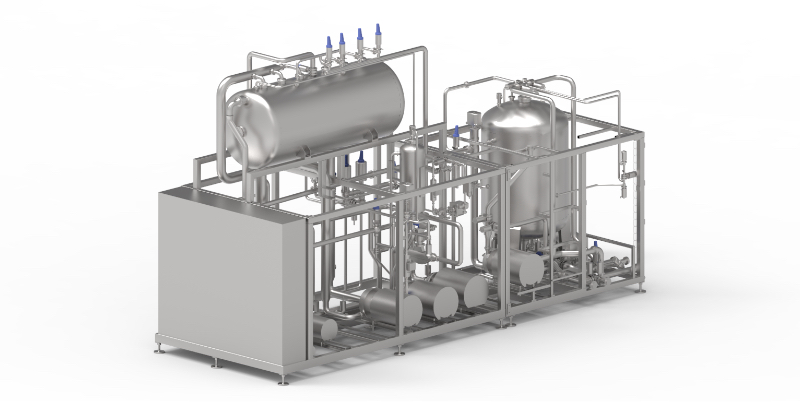

Success in water beverage production requires focus on maximum output and efficiency, with commitment to hygiene, food safety, cost optimization and sustainability. Whether you're producing still or sparkling water, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

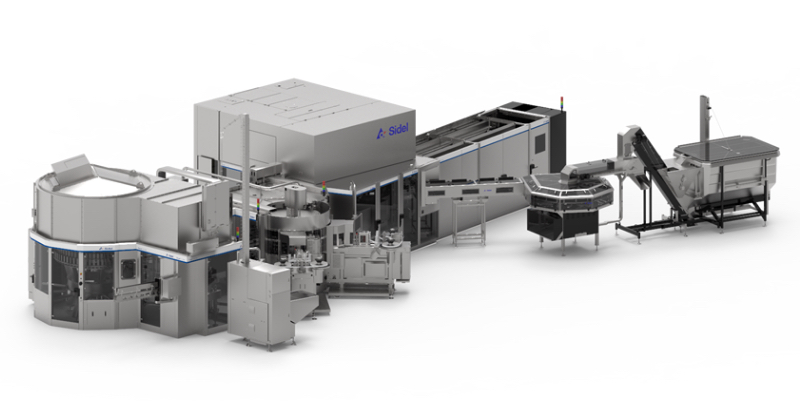

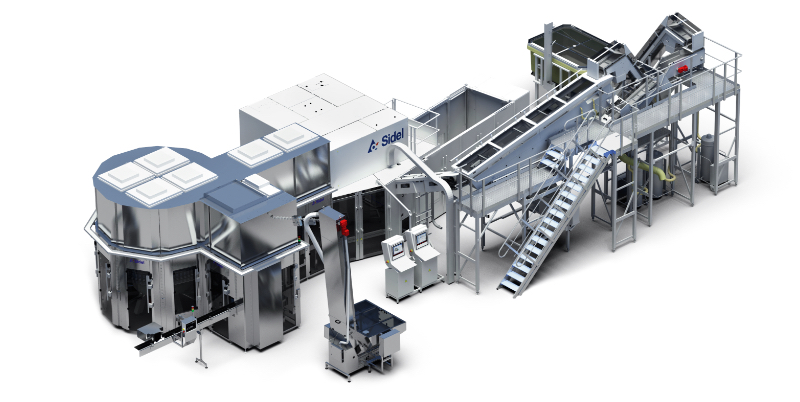

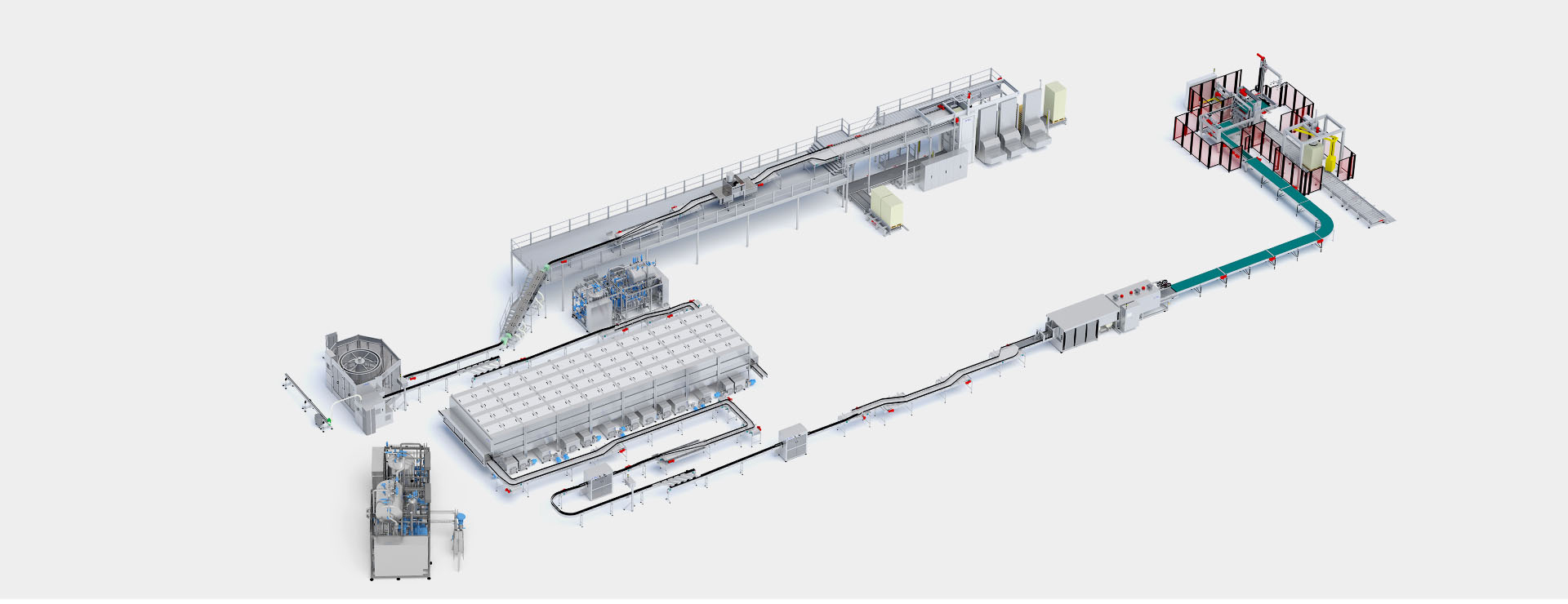

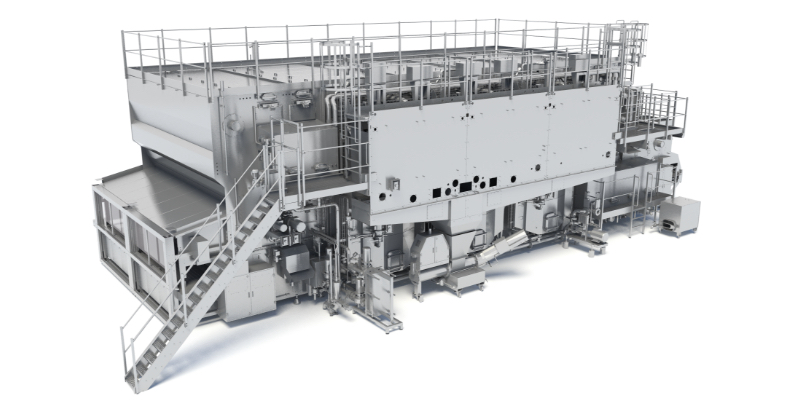

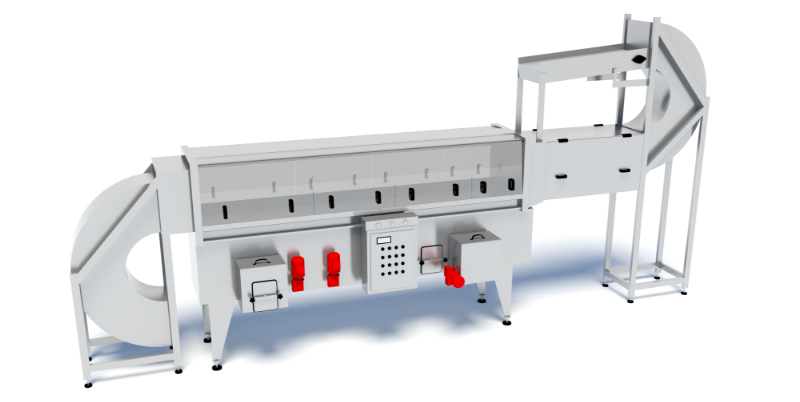

With over 40 years of experience in designing and implementing customized complete PET line solutions for water, we can help you reach your production targets. Over the years, we have significantly reduced the weight of water bottles and hence the carbon footprint of our customers, while retaining bottles durability and expanding design opportunities.

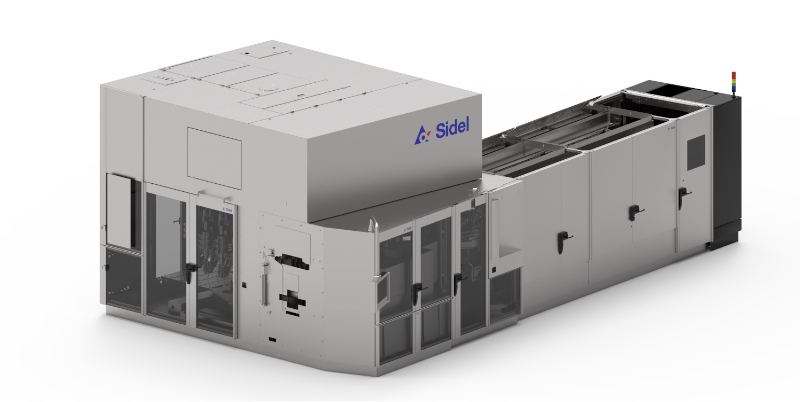

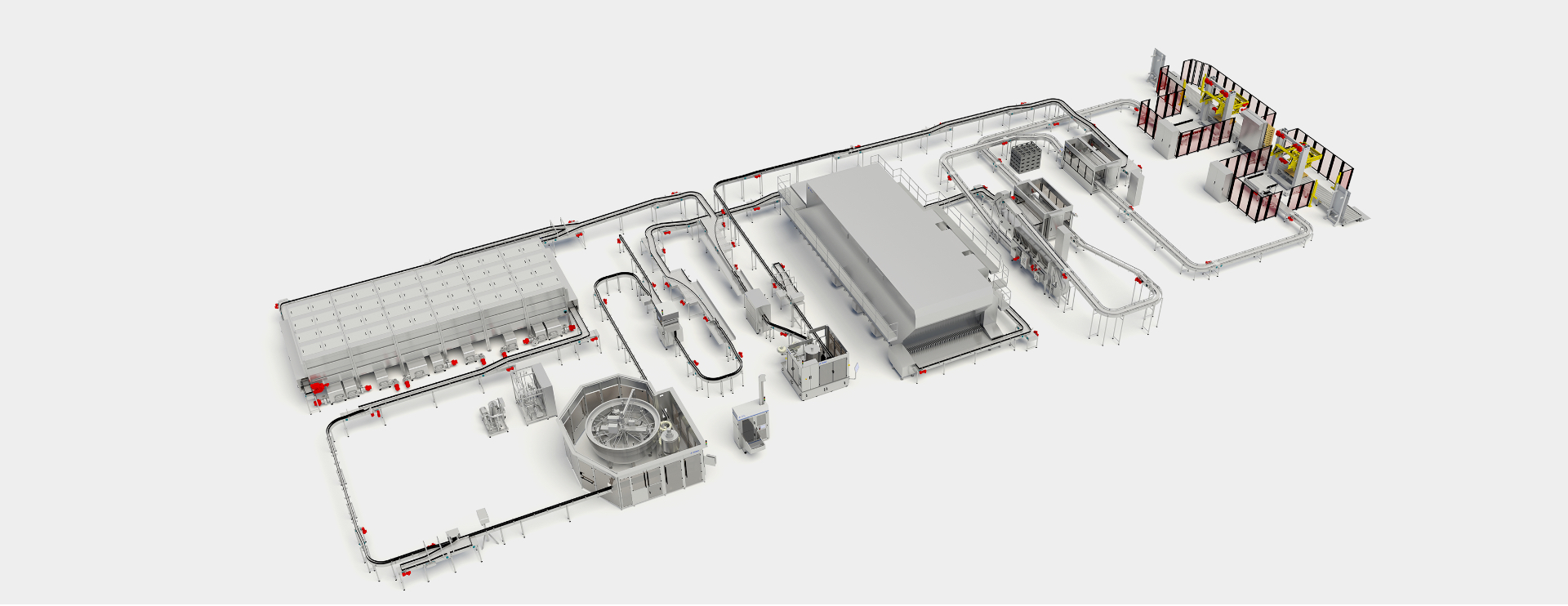

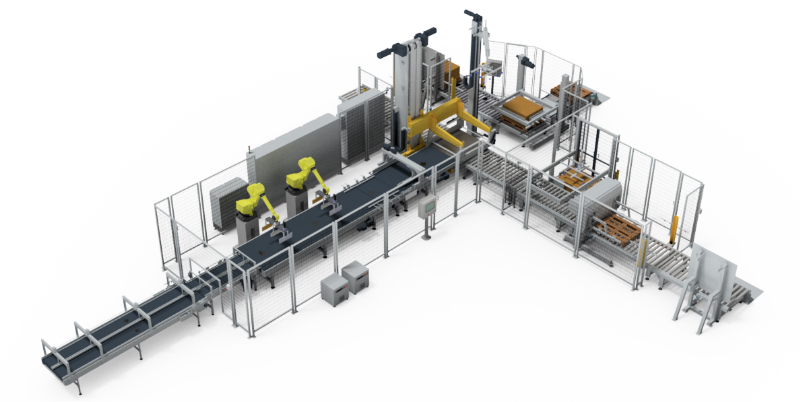

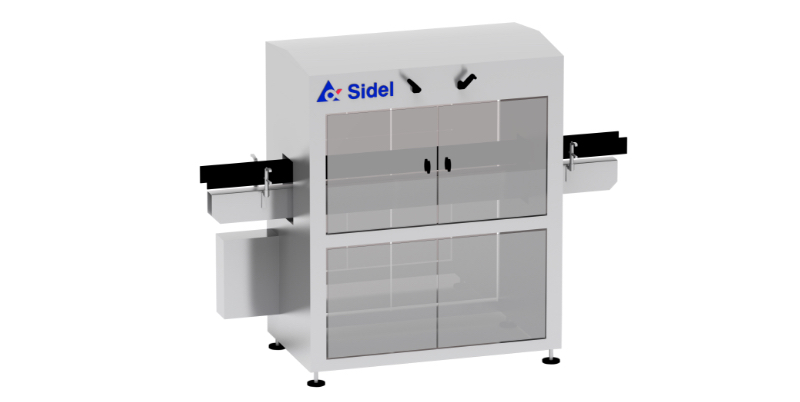

One partner for all your needs

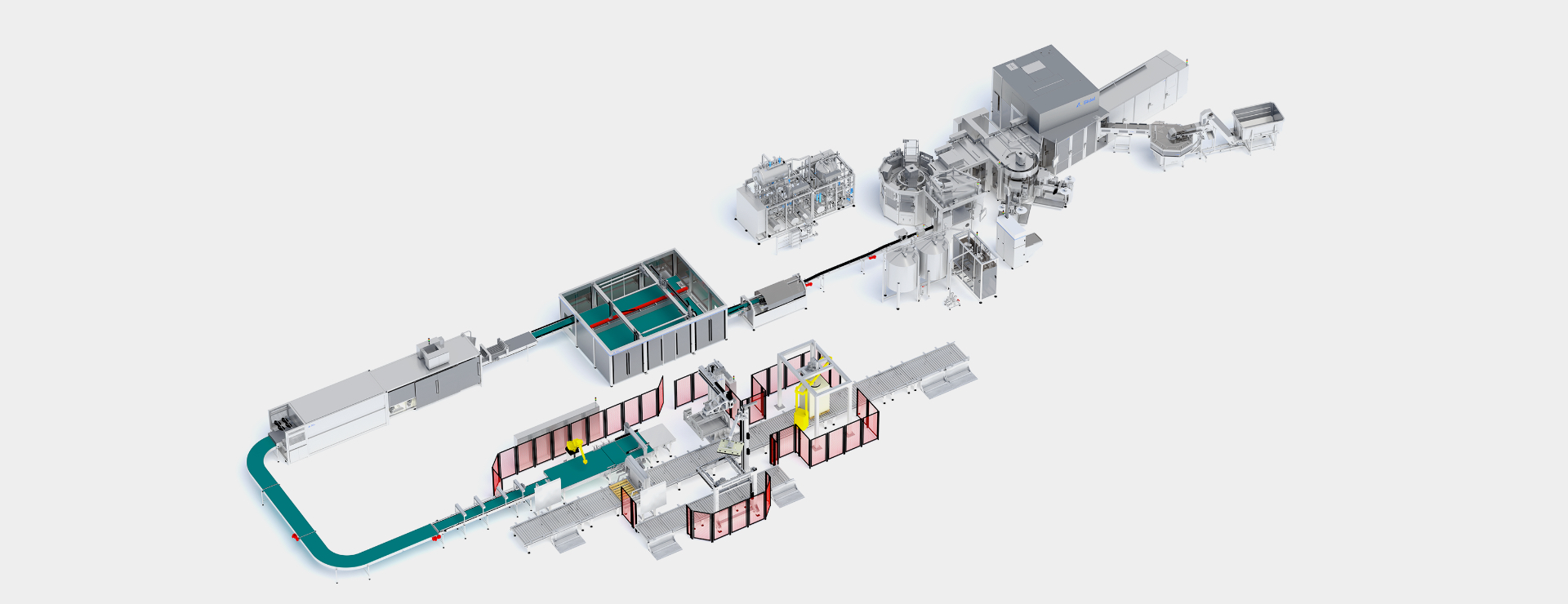

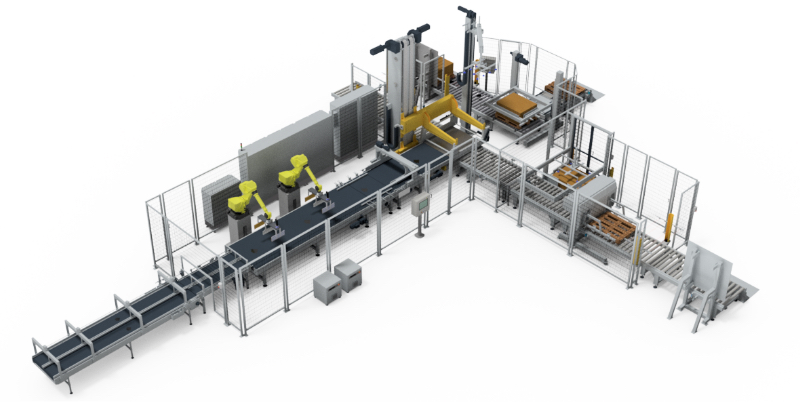

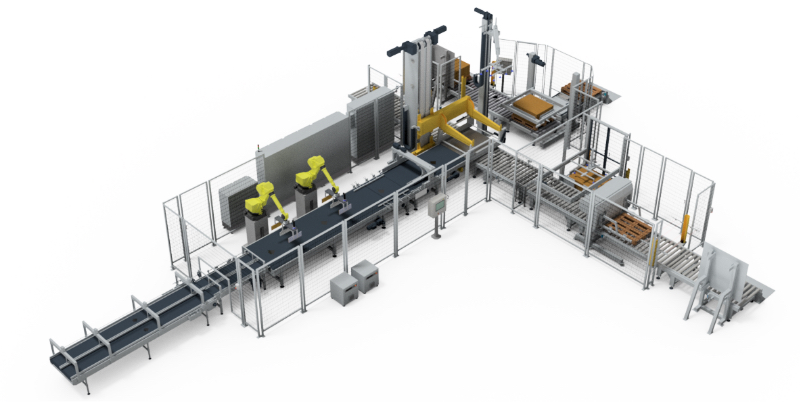

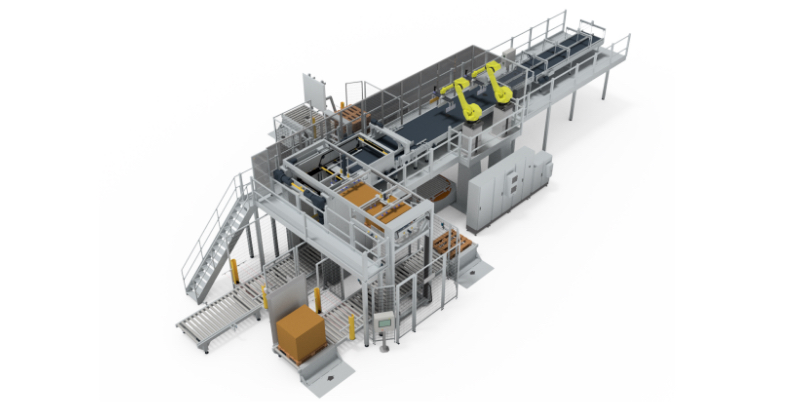

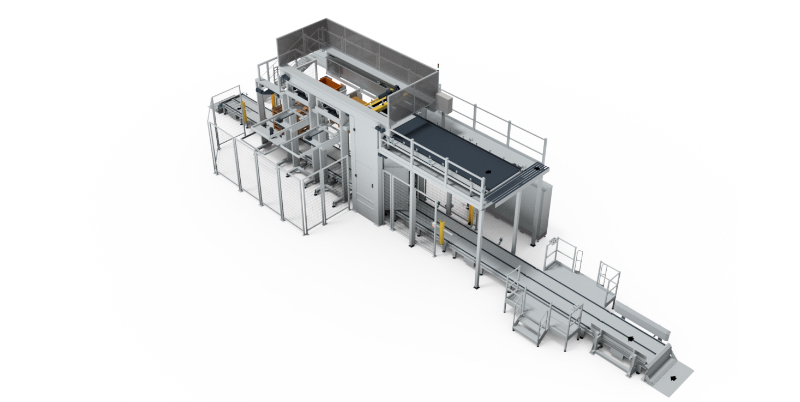

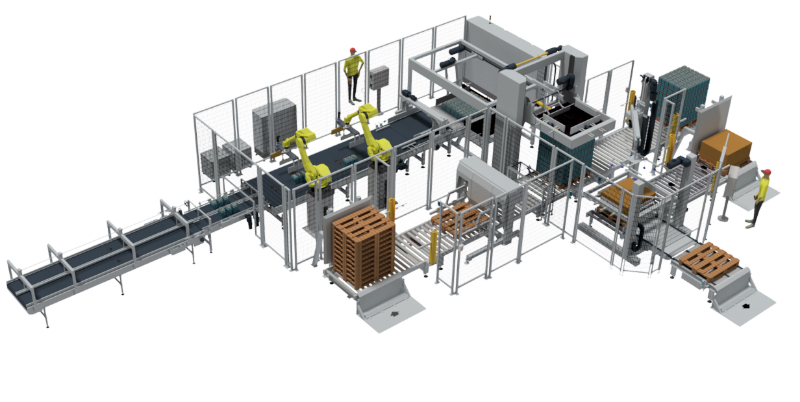

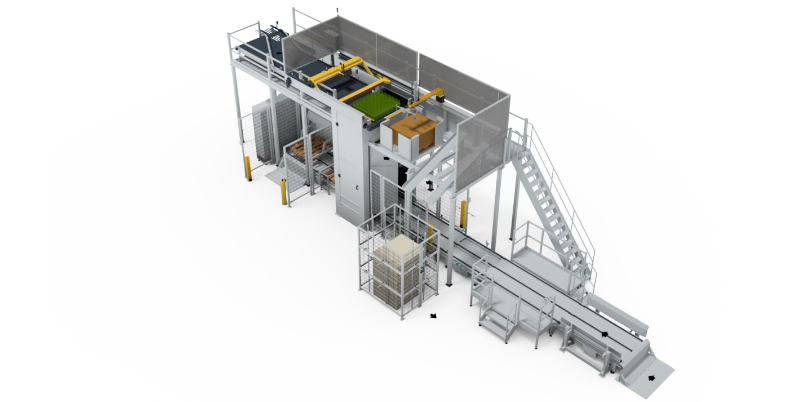

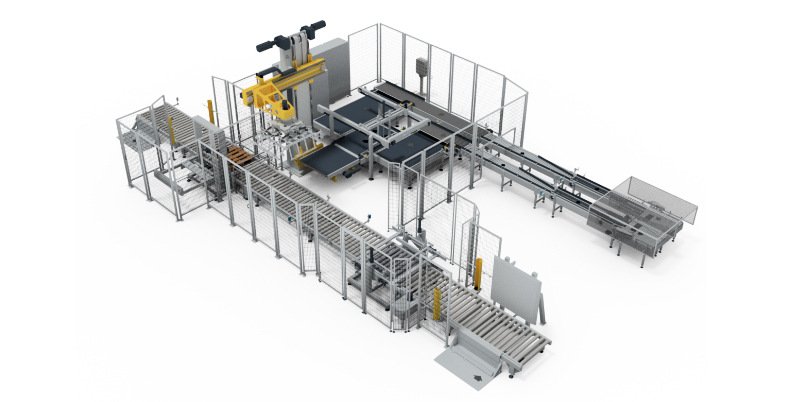

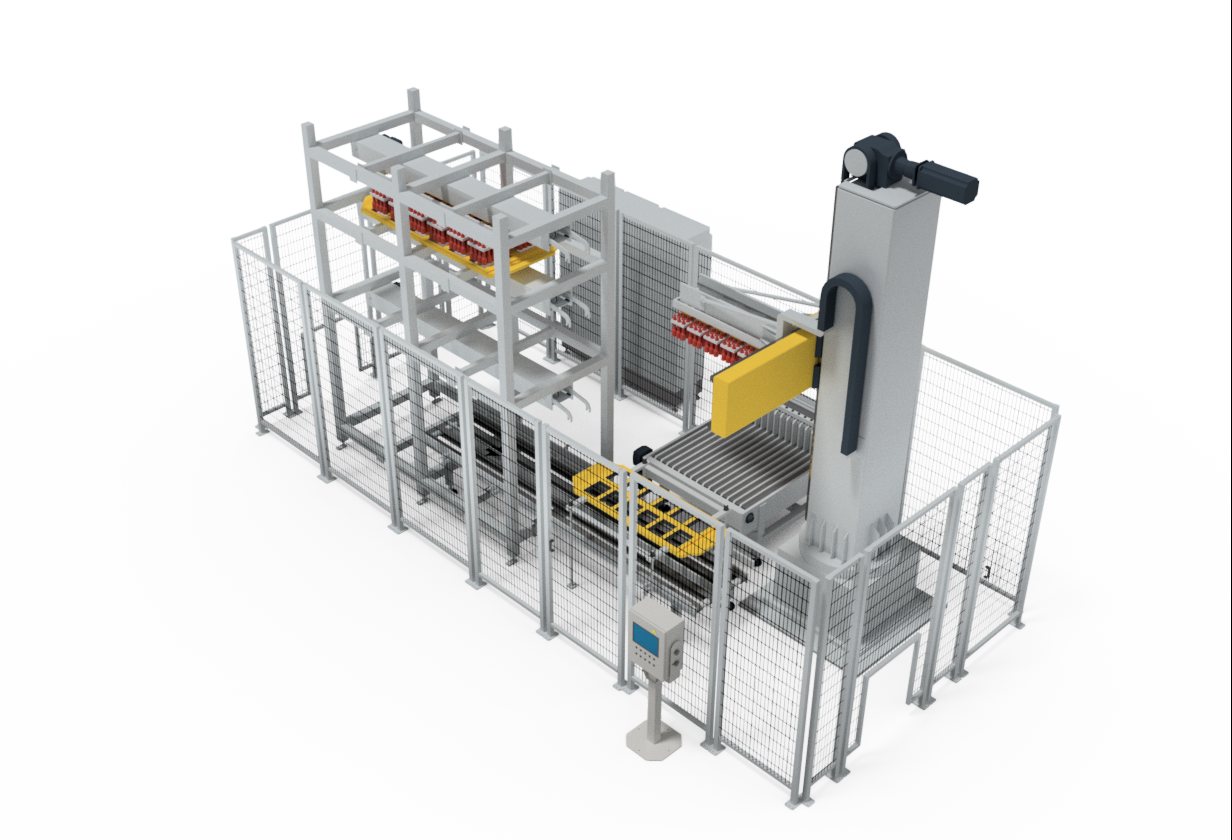

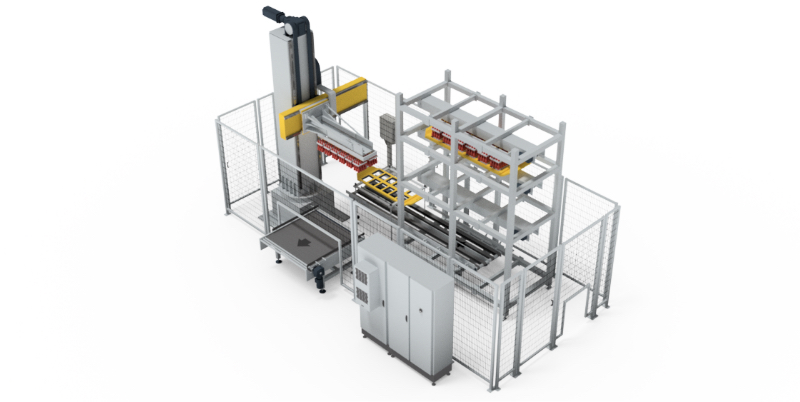

A complete water line solution from Sidel leverages our knowledge of the entire water bottling process, from minimizing waste of resources to helping you achieve your sustainability targets, to ensuring that your bottle is durable and attractive to consumers. With everything centered around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.

Always by your side on every step of the way to build, maintain and improve your line performance