When the pack is also the selling unit, its quality obviously needs to be impeccable and the product brand must be perfectly visible. 2 or 3 lanes are often used to handle these smaller packages efficiently and hence channels are required in the shrink tunnel in order to convey hot air into the right spots so as to obtain the best possible shrinkage.

Cermex’s Versafilm® system meets these requirements and represents the next generation of shrink-wrapping technology:

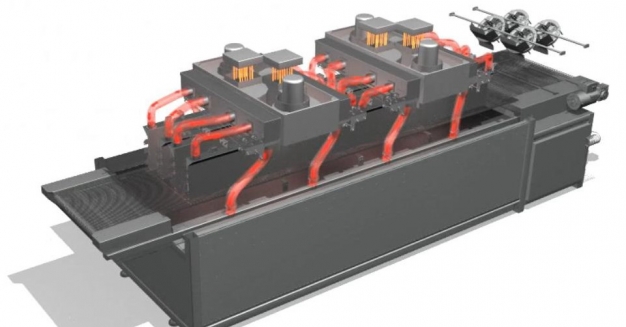

- A multichannel shrink tunnel with 1 to 3 lanes

- Hot air circulation that can be adjusted to match the needs of each specific product format in terms of height, collation and number of lanes.

- The operator can set the blowing height in each air channel

- The inter-channel spacing and individual air flow can also be modified instantly, ensuring higher quality film shrinkage and huge savings in terms of energy consumption.

Change reels without stopping

The new vacuum infeed table features a seamless automatic reel changeover function, based on a patented Dual Injection System (DIS), allowing the machine to change reels without even stopping. Versafilm® also offers superior flexibility, with a fully-adjustable pin gating system capable of running at anywhere between 10 and 120 cycles per minute.

Benchmark-setting innovation

The combination of Versafilm® with EvoFlex® along with the company’s integration expertise to form VersaBloc® is a totally unique proposition: a high-performance, ergonomically-designed end-of-line system incorporating both overwrapping and palletizing functions. It offers superb energy efficiency, as well as slashing TCO costs by as much as 8%. A feat made possible by the marriage of two patented technological breakthroughs and the company’s longstanding expertise.