Last but not least, compactness has really been the key deciding factor. “The alternative of having a lane divider feeding the traditional channels of the shrink-wrapper, consequently avoiding mass accumulation, was not appropriate in terms of the footprint. In fact, the area taken by the divider and its conveyors upstream and downstream would require too much space while reducing the circulation around the line,” explains Valérie Cattenoz, Overwrapping Product Manager at Sidel. In addition, managing different SKUs in tray and film, in principle contradicts the availability of a very compact solution, as tray modules usually automatically lead to a bigger layout of the shrink-wrapper.

Fast and automatic changeovers with streamlined unifilar infeed system

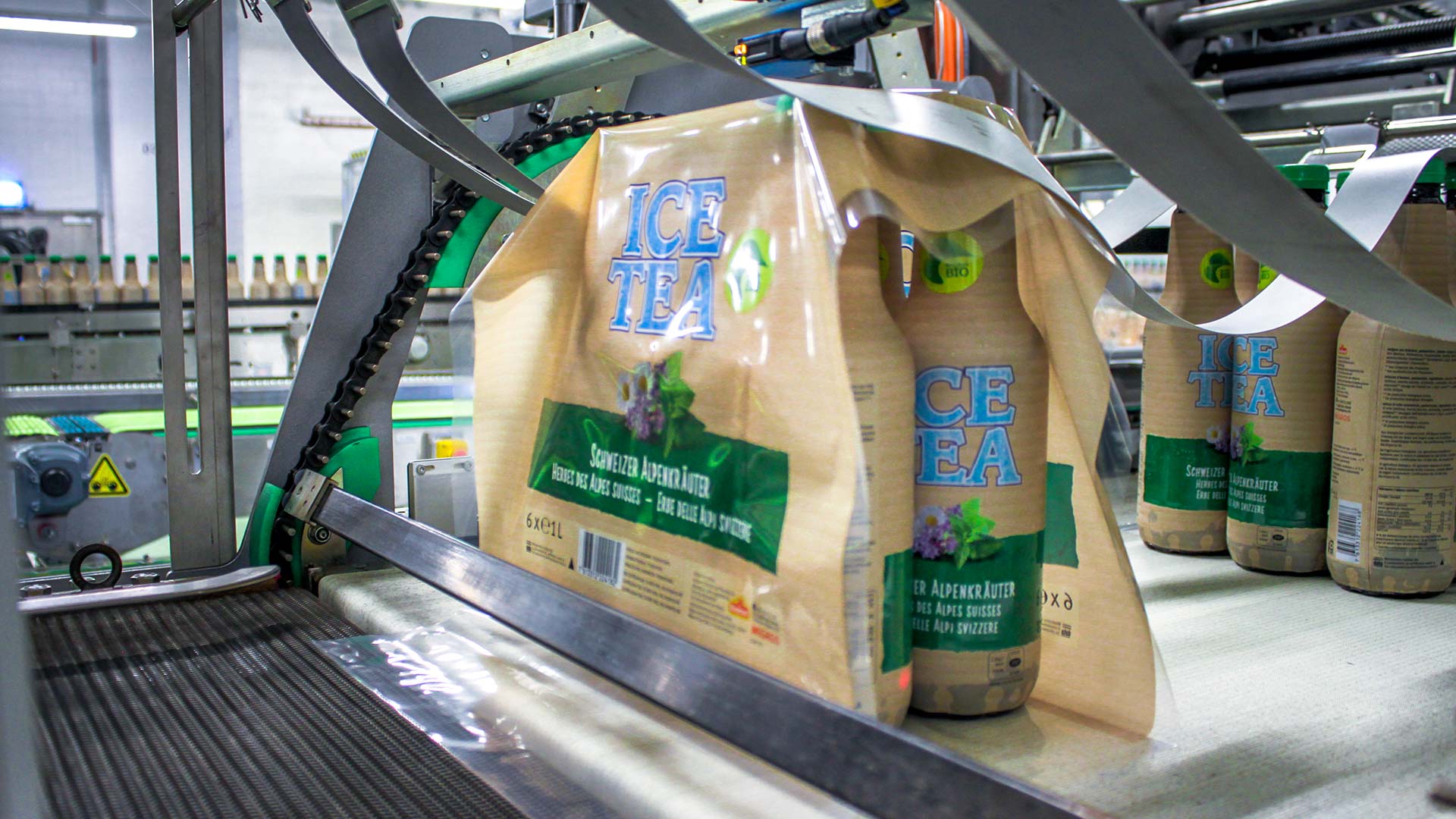

“We evaluated various possible solutions and Sidel’s new infeed system was the only one allowing a one-of-a-kind, compact line layout with the guarantee of no jamming at the shrink-wrapper’s infeed due to its design,” Yasin highlights. The new shrink-wrapper is equipped with a very compact and reliable unifilar 90° infeed system where the flow is managed on one lane – directly from the sleeving machine with no lane dividing system needed. The flow of juice and iced tea bottles is instead going straight to the shrink-wrapper.

The high reliability of this innovative and unique infeed secures a very critical part of the shrink-packer, allowing the management of any shape of bottle, round or squared. Valérie explains the unique design, “First, a selecting device with lateral brackets delivers the right number of products per row while ensuring the necessary distance between each row. These rows are then transferred at a 90° angle by an ‘on the fly’ pusher, which redirects the flow of three to five bottles[2] in accordance with the shrink-wrapper’s flow direction.” The installed system is technically capable of running at a maximum speed of 150 cycles/minute, depending on the exact product size and shape. “The solution is complemented by a tray module, delivering tray plus film packs,” she adds.

For changeovers, the proven shrink-wrapping solution embeds automatic and easy-to-adjust systems, with operators guided through each step directly via the HMI. Most of the adjustments are done automatically, while the non-automated ones are supported by LED digital counters. The latter ones ease and speed up the process while securing it, because they are blocking the machine from restarting if the expected settings are not met. “We appreciate the simple, streamlined unifilar infeed system where all changeover tasks are carried out automatically in three minutes, delivering a maximum changeover time of 15 minutes for the entire shrink-wrapper – worst case scenario when moving from film only to tray plus film or vice versa,” says Yasin.

Increased ergonomics and compactness for a successful project

To also accommodate the need of the tray plus film option, Sidel designed a removable rolling tray magazine, which can be extracted from the shrink-wrapper when running a format without tray support. The circulation around the line is then much easier for the consumables and the operators. It is, in essence, a Plug & Play module with a central cabling connector. In a traditional solution, the tray magazine is typically located underneath the product infeed. Thanks to the 90° infeed configuration, the upper part of the magazine is now open and accessible and therefore allows an easy and ergonomic manual refilling of the trays in the magazine.

Yasin sums up the success of the project for the Swiss company, “From project planning to implementation, the collaboration with Sidel worked well. The challenges that arose were approached in a structured way and handled in a professional manner. For us, the greatest advantage of the Sidel solution lies in the space saving from the infeed system.”

[1] Euromonitor International 2019

[2] The number of bottles depends on the chosen collation