In over 40 years’ experience of blowing and PET packaging, our engineers have developed a comprehensive understanding of rPET (recycled PET) and its impact on bottle production. They have now leveraged this knowhow to create a new hub of expertise: RePETable™, the 360° one-stop shop for recycled PET. From designing packaging optimised for recycling to securing efficient rPET bottle production, the RePETable™ range allows packaging industry players to pick the services that best fit their PET circularity needs.

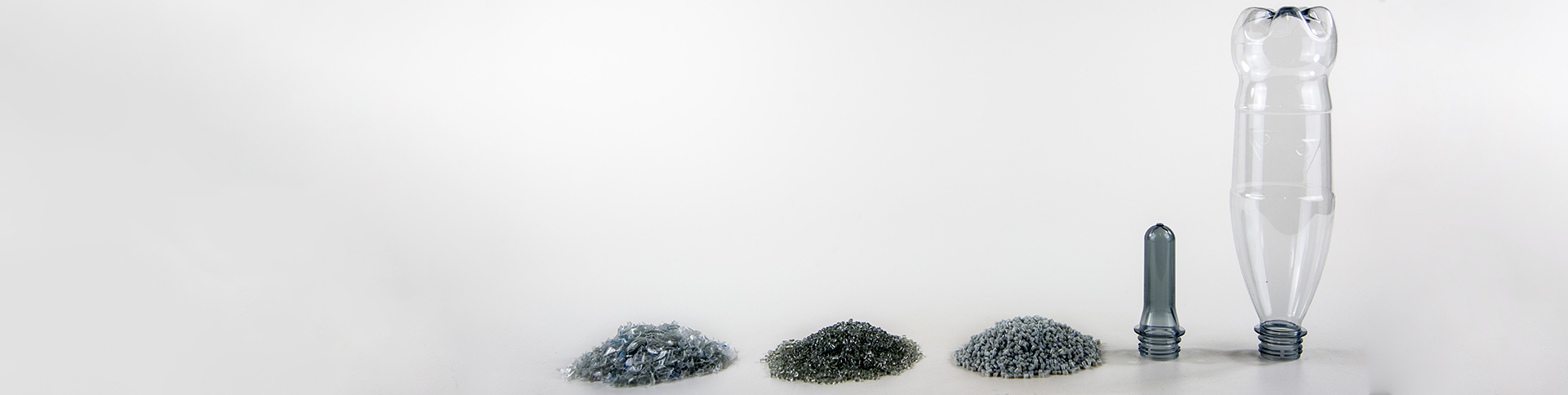

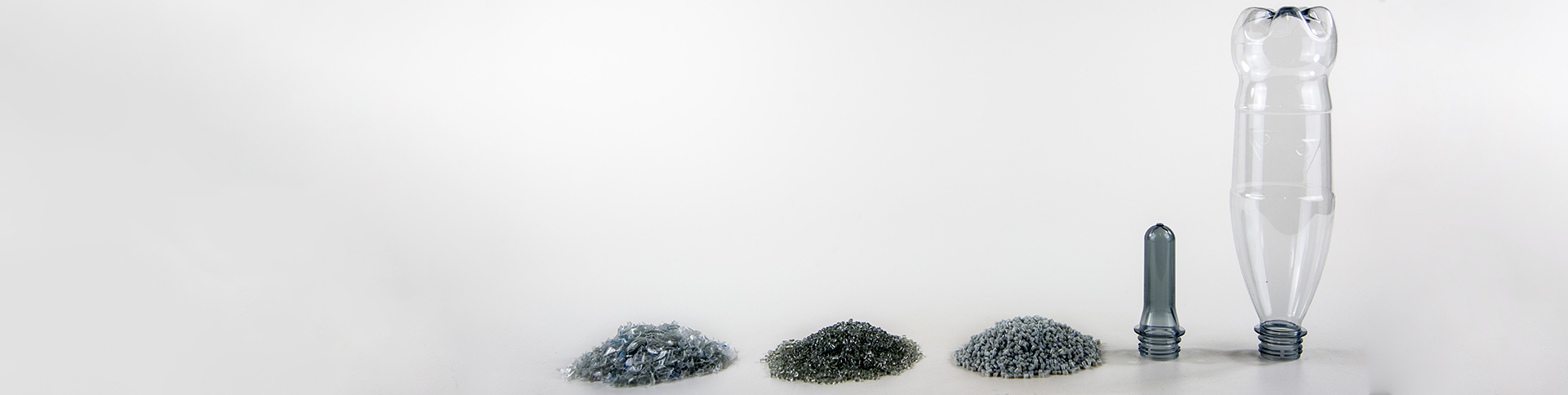

Our experts therefore analyse every aspect in the recycling and bottle production processes, including post-consumer PET bales, flakes and the pellets to be injected into the preform as well as rPET bottle blow moulding and industrialisation.

This bottle-to-bottle approach ensures:

To reach the same level of performance as virgin PET, the recycled PET bottle production process needs to adapt to the resin used. RePETable™ therefore offers a range of solutions to achieve this and secure production efficiency and bottle quality whatever the rPET percentage.

Sidel’s small-scale recycling pilot line is part of the RePETable™ mission to support robust PET circularity. It helps the market innovate with new materials for primary packaging (closures, sleeves, glues, labels, additives and colouring…) while ensuring they are designed-for-recycling.

The pilot line recreates every step in the recycling process, including: