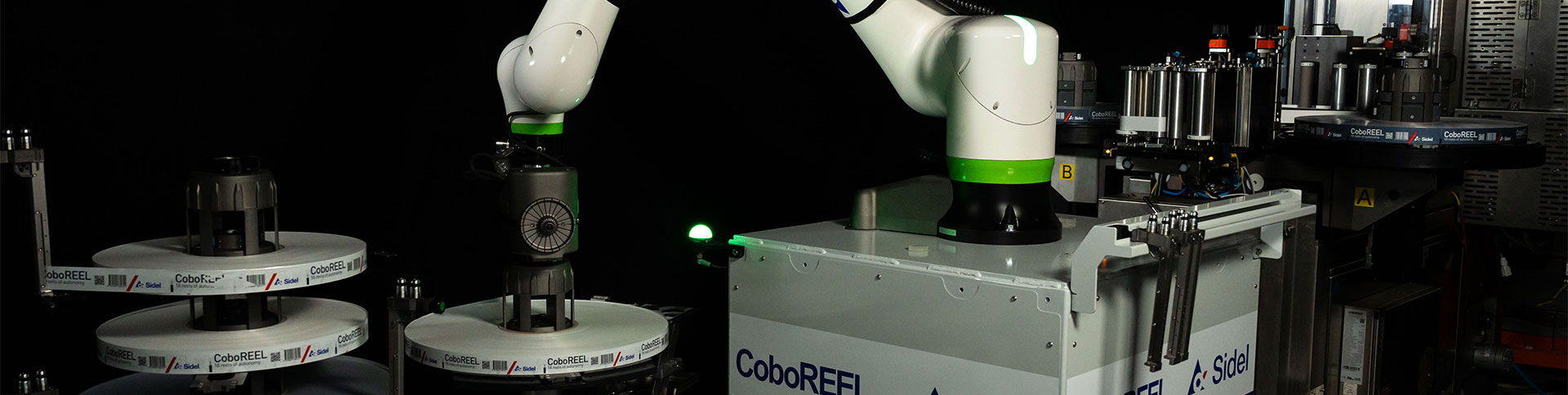

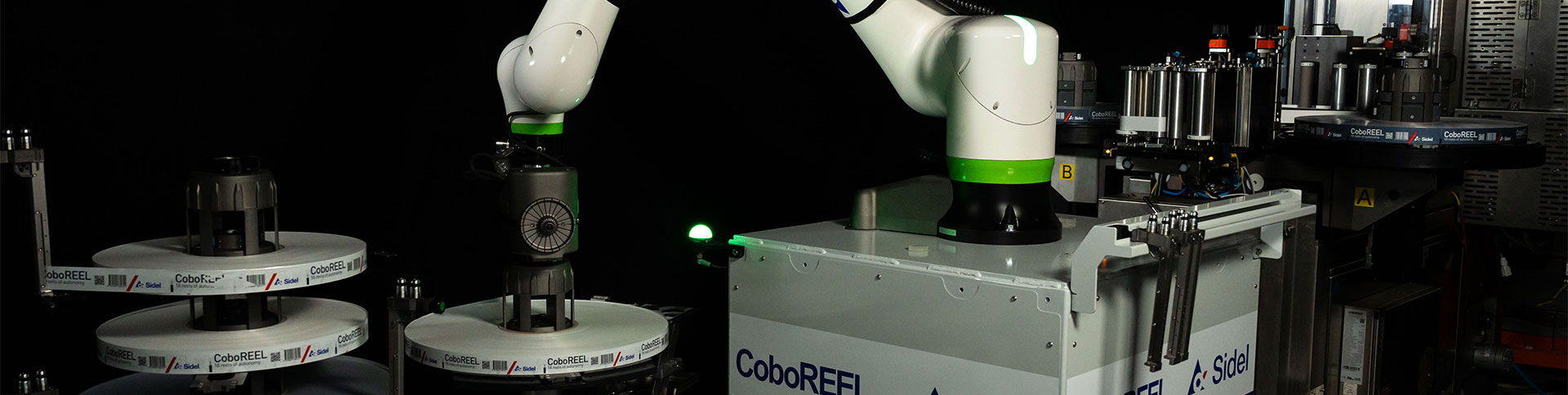

By integrating collaborative robots to automate the reel-loading process, CoboREEL’s 18-reel capacity significantly enhances labelling performance, ensuring 100% accuracy, optimising efficiency, and increasing profitability.

Automating this simple, repetitive task with cobots allows manufacturers to work smarter, using fewer resources in a more efficient and intelligent way. It reduces downtime caused by manually changing individual label reels and delivers maximum precision, minimising the risk of errors, delays, or misplacements that can cause unplanned machine stops and productivity losses.

After feeding the CoboREEL at the start of a shift, operators are freed from this repetitive task of manual reel loading and can instead focus on more complex and interesting tasks which in turn improves focus and productivity.

Designed to be intuitive and easy to use, CoboREEL requires no maintenance and demands minimal technical expertise ensuring the lowest total cost of ownership. In environments with frequent staff turnover, it offers a user-friendly solution that can be quickly adopted without the need for specialised skills or long onboarding.

Working as a standalone unit, CoboREEL can be easily moved and deployed across different modules as required, offering producers exceptional flexibility.

CoboREEL’s unique, safety-first design is compact and flexible, with embedded traceability, able to manage different label types and designs autonomously. Its low energy consumption also helps manufacturers reduce their environmental footprint.

Always by your side on every step of the way to build, maintain and improve your line performance