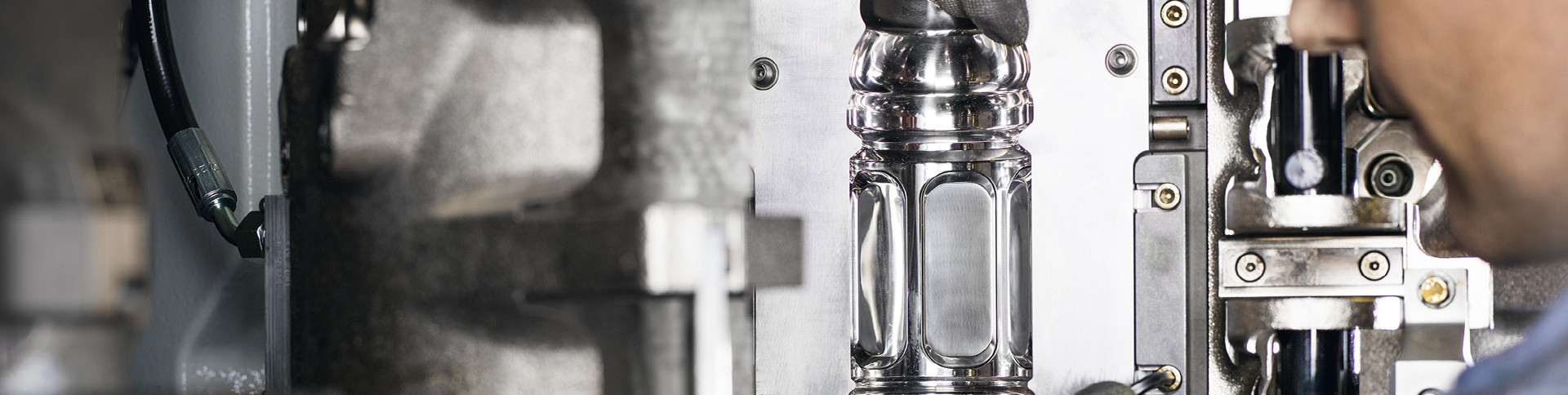

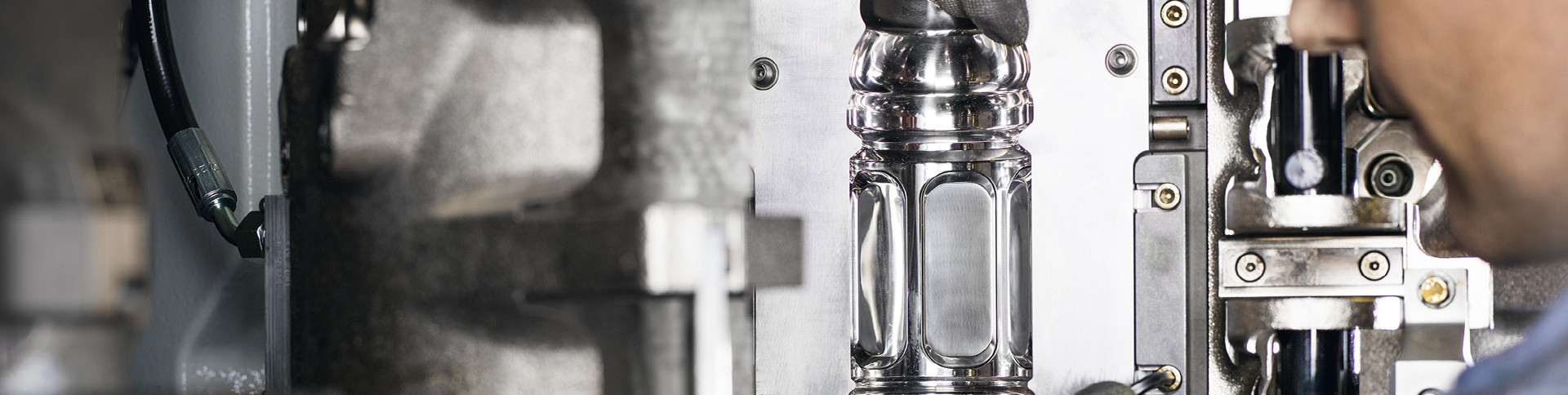

The full range of Sidel moulds is engineered for any demanding production speeds and is thoroughly tested to ensure the quality of your PET containers. With more than 40 years of PET packaging expertise, we can support you at every step of your new container project, from packaging engineering to moulds and parts delivery.

With more than 24,000 moulds produced annually in our five Mould, Line Conversion and Packaging centres worldwide, we can quickly provide solutions to customers in all continents.

Fast expert support worldwide for any project

Our 200 Sidel Mould and Line Conversion specialists, located across the globe, provide smooth, exacting project management. They offer excellent responsiveness to ensure that you are able to quickly bring your product to market.

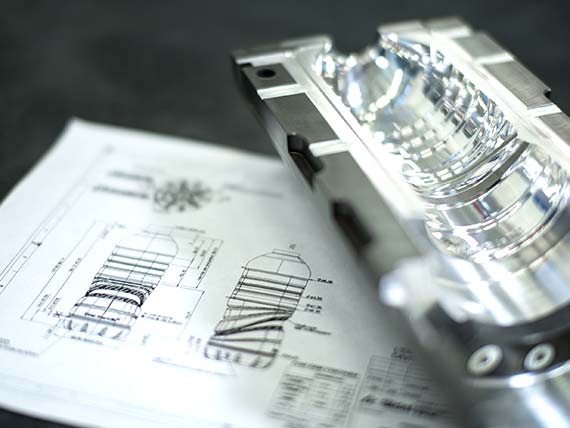

Sidel Packaging designer team can also support you in engineering the right PET container for your product. Learn more about our packaging capabilities here

All our original moulds are produced by Sidel experts, who carefully provide customer solutions that keep performing over time:

All moulds are certified for maximum uptime and are warrantied to last. As a guarantee of quality, Sidel commits to your final bottle specifications.

A mould for every container

Each project is different. Sidel engineers design unique moulds that can fit with any type of blower and blowing process. The 500,000+ Sidel moulds sold over the last 40 years attest to mould expertise that can optimally address your container project:

Regardless of the generation of your blower, you can maintain performance thanks to our mould and parts regeneration services:

Benefit from OEM standards and quality to manage the lifecycle of your machine.

Line Conversions

Our customised solutions allow you to handle new PET package on your existing manufacturing lines. Learn more about our Line Conversions capabilities here