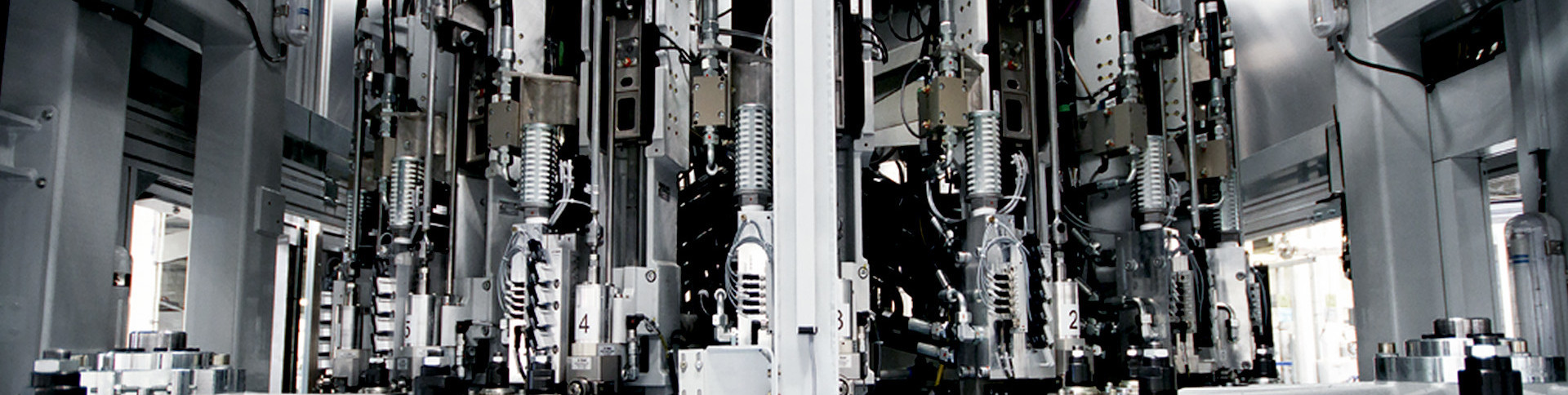

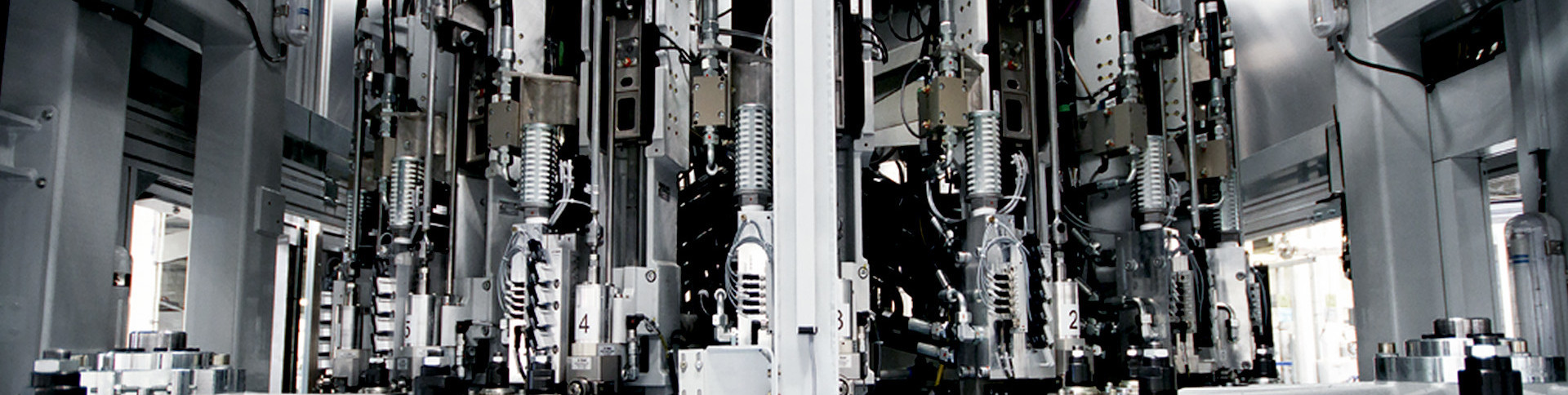

Ensure highly consistent bottle quality for your hot-fillable and pasteurisable PET bottles by making use of the processing capabilities of the Sidel EvoBLOW eHR blower range with electrical mould heating.

When hot-filling sensitive beverages like juices, nectars, soft drinks, isotonics and teas (JNSDIT), in order for them to be filled safely, the bottles are heated to a temperature between 80° and 95°C.

To withstand those temperatures, PET bottles are produced via a heat-resistant, stretch blow moulding process, commonly referred to as HR (heat resistance) or heat set. The process is based on higher preform reheating capability and blowing bottles in hot moulds, usually at temperatures above 120°C.

The revolutionary Sidel EvoBLOW eHR blowing solution replaces heating of the mould for the bottle body, traditionally carried out with oil. Instead, heating is via electrical resistance creating a temperature increase that is three times faster.

This process achieves numerous operational benefits in terms of bottle quality, performance, process flexibility, uptime, energy savings and operator safety.

| SBO6HR | SBO8HR | SBO10HR | SBO12HR | SBO14HR | SBO16HR | SBO18HR | SBO20HR | SBO22HR | SBO24HR | SBO26HR | SBO28HR | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Output rates (up to, in bph)* |

12,000 | 16,000 | 20,000 | 24,000 | 28,000 | 32,000 | 36,000 | 40,000 | 44,000 | 48,000 | 52,000 | 56,000 |

*bottles per hour - Maximum mechanical output rate, with a speed up kit, according to the bottle's features

| Maximum bottle volume (depending on bottle design) | 2 l |

|

Maximum bottle under neck height (heaters lenghts) |

300 mm |

| Maximum bottom height | 51 mm |

| Maximum overall diameter (with mould adjustable panels) | 105 mm |

| Maximum overall diameter (without mould adjustable panels) | 110 mm |

| Maximum preform under neck height (with 10 lamps heating unit) | 145 mm |

| Maximum ring diameter | 48.3 mm |

| Maximum ring height | 24.6 mm |

The eHR blower shares a number of commonalities with the standard configuration of Sidel EvoBLOW blowing architecture. For example, mechanical settings are the same and 73% of the eHR blowing station components are similar to those of standard Sidel EvoBLOW blowers. But furthermore it benefits from all the most recent and proven Sidel technologies used for regular production of PET bottles including:

Sidel's eHR blowing process is very responsive. Mechanical output reaches up to 2,000 bottles per hour per mould. Temperature variation and discrepancies between different blowing stations are kept to an absolute minimum.

Sidel EvoBLOW eHR blower offers great savings in terms of electricity and air consumption, through its innovative electrical mould heating and the proven Sidel EvoBLOW blower technologies.

By eliminating hot oil altogether, the design of the Sidel EvoBLOW eHR blower prevents hazards caused by the leaking of oil, such as operators' slipping and the contamination of filled bottles.

The new blowing process using heating by electrical resistance is used in the Sidel EvoBLOW Combi Hot Fill, complementing the advantages of the standard Combi configuration that integrates the blowing, filling and capping functions in a single enclosure.

EvoBLOW eHR offers great production flexibility thanks to fast and error-free changeovers:

Always by your side on every step of the way to build, maintain and improve your line performance