Top hygiene: a must-have for the best product quality

Addressing top hygienic requirements, EvoFILL Can’s “no base” design, which as a whole is very accessible, ensures an overall easy cleaning and no residual of product in the filling environment. The solution’s improved CO2 pre-flushing system results in utmost food safety, as there is no residue and a cleaner zone. Consuming less CO2 in total, this feature improves beverage quality and leads to greater performance. For beer producers, this means lower O2 pick-up, down to 30 ppb, nonetheless saving resources.

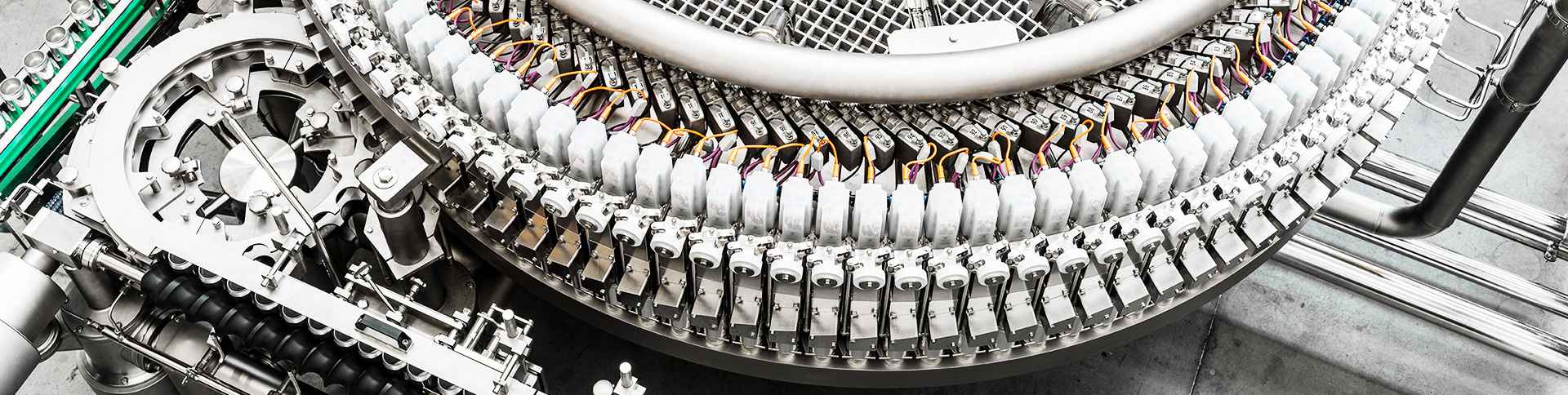

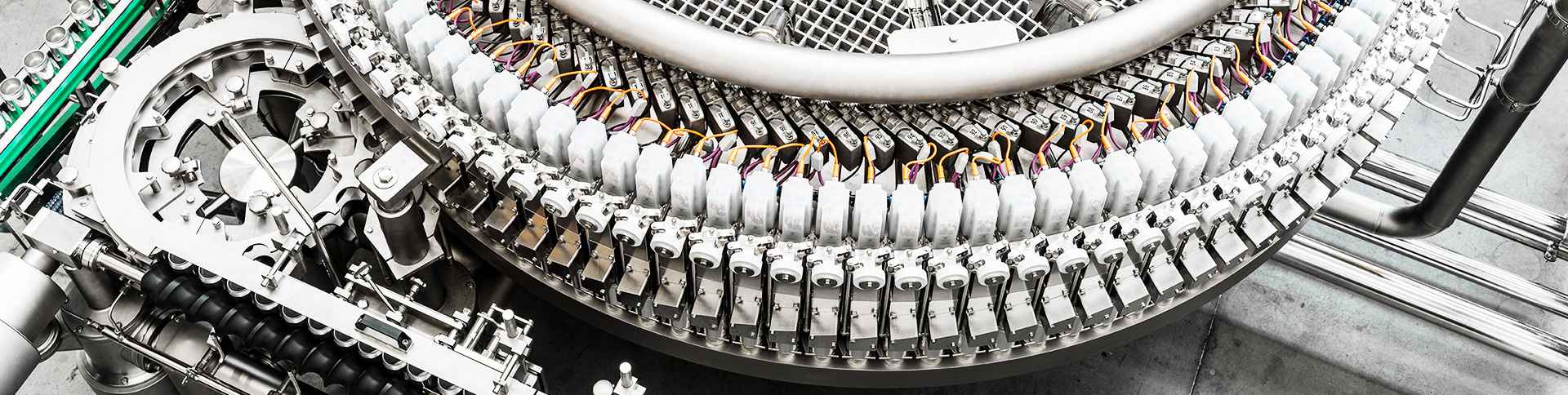

With a single or double can infeed available EvoFILL Can allows for a flexible upstream line configuration. With the solution operating at high speeds of over 130.000 cans per hour (cph), the double infeed allows for the best can quality as containers suffer much less stress and no damages. As hygiene is a key component for the overall product quality, Sidel’s engineers developed a new drive system, enabled by servomotors. It requires no mechanical transmission between the filler and the seamer, thus eliminating any need for lubrication and any moving parts in the filling area.

The new drive system also leads to better accessibility, which speaks to the greater ergonomics of the solution, and minimises TCO through savings on maintenance and energy. Additionally, because no water is needed for the lubrication of rollers, it cannot drip down during the filling process nor remain inside the filling environment, potentially contaminating the product. For utmost hygiene, the design of the solution has been optimised further: it now includes fully cleanable handling parts with reduced top surfaces. Therefore, cleaning is more effective and there is no risk of chemical agent or water residual.

Unique features making the difference

What sets EvoFILL Can apart from other solutions on the market is its external beverage tank and integrated small chamber. This concept ensures a better and more effective cleaning of all parts that come in contact with the beverage. Plus, the chamber is completely full and accommodates the product only, making the cleaning easier and reducing costs of maintenance. On top of this, the external tank acts as an enabler for the Sidel BlendFILL configuration, the compact solution which combines the mixer and the filling buffer tank in one single skid. BlendFILL is a safe and hygienic solution with much fewer components and functions that avoids redundant pressure and level control functions, reduces consumption of CO2, as well as the equipment footprint, and minimises product waste when switching between beverages.

Performance and sustainability: the ideal recipe to reduce TCO

With an efficiency of 98.5%, the new EvoFILL Can significantly reduces TCO: the solution has the best filling accuracy – 1ml standard deviation (≤ 500ml cans) – thanks to the new valve design, which generates less product waste. Additionally, with an increased lifetime of 12,000 hours before replacement, the main components of the filling valves significantly reduce downtime for maintenance and relative costs.

For higher overall line availability, star wheels and guides are built in light-weight sectors for easy and quick replacement, with changeovers possible in less than 30 minutes. Maximum uptime is also secured through the integrated pneumatic box: this feature – an industry first – makes maintenance and access to the filler carousel easier, as there is only one pneumatic box per valve and zero pneumatic pipes in the filling environment. These are only a handful of features that demonstrate how the solution contributes to a sustainable business performance.

Staying ahead with greater beverage and format flexibility

Without compromising the performance of the line, a wide range of beverage temperatures can now be processed: beer can be filled up to 18°C and CSD over 20°C. All of this eliminates the need for a chilling unit, thus achieving massive energy savings.

With 54 to 182 filling valves on EvoFILL Can’s carousel, manufacturers are able to handle a wide range of speeds and can sizes, from 150ml up to 1L. The new valve centring bell design eliminates the need for changeovers of all possible can-end types in the beverage industry – from 200 to 209 – for maximised uptime. Likewise, the varying height of the cans is no longer a challenge, as the carousel adjustment is fully automatic. To further demonstrate its unprecedented flexibility, EvoFILL Can has the capacity to fill CSD at ambient temperature and still drinks in hot-fill, thus accommodating a wide range of beverages via a single piece of equipment.

“At Sidel, product quality and an advanced level of performance are important drivers for our innovations. With the new EvoFILL Can, we are perfectly meeting these requirements: the solution tackles all needs of being sustainable, hygienic and flexible, getting producers ready for future challenges in canned drinks production,” concludes Stefano Baini, Product Manager Filling at Sidel.

More information on Sidel EvoFILL Can: sidel.com/evofillcan