15/11/13

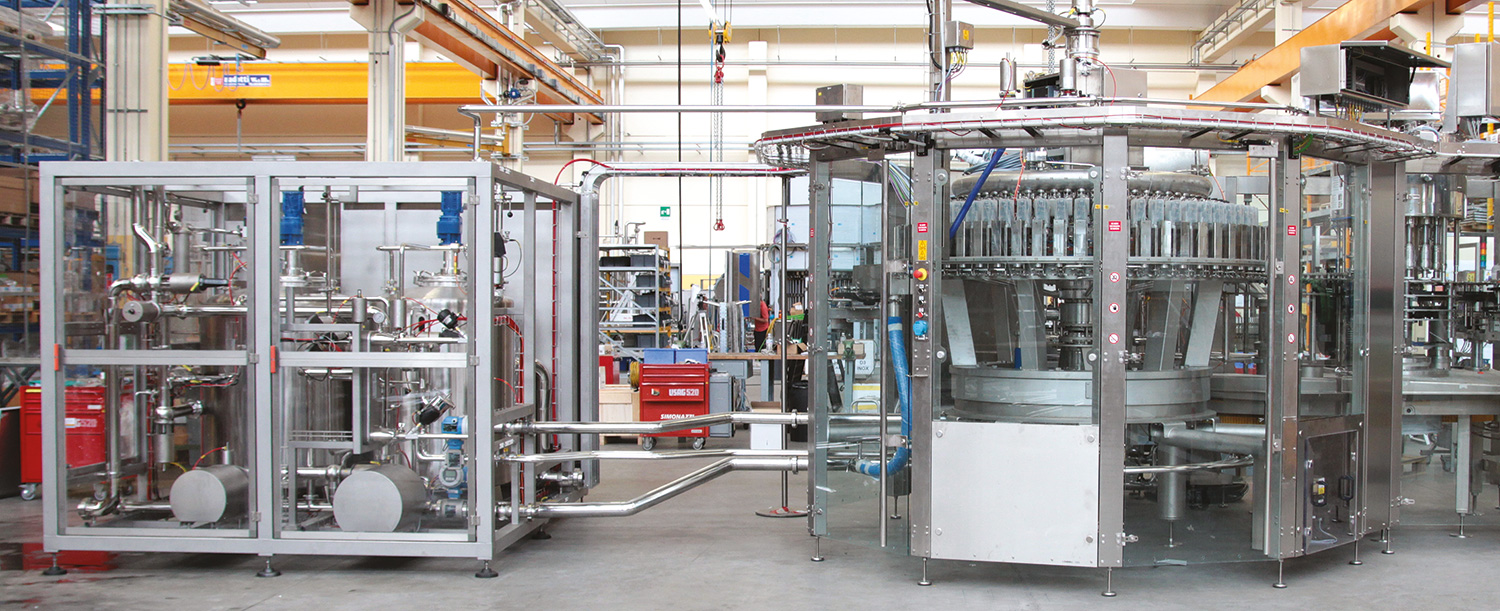

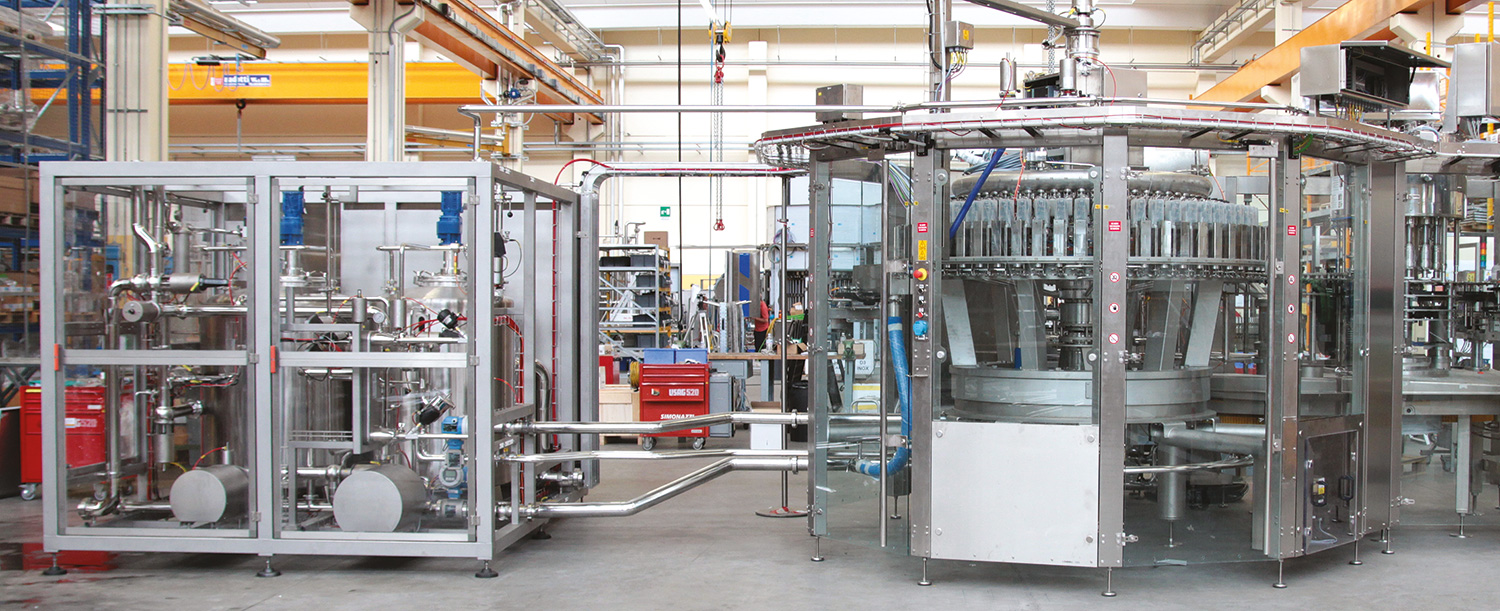

The radical, modular Sidel Matrix hotfill system hasbeen developed to ensure the levels of product safety and qualityrequired by the fastest growing segment of the beverage industry.This includes juices, nectars, still drinks, isotonics and tea(JNSDIT). It is part of Sidel's global Matrix solutions configuredto provide a revolutionary level of process flexibility with anincreased production capacity for a broad range of beverages.Backed by reliable operations to meet the exacting requirements ofliquid producers, Sidel Matrix solutions include blowers, fillers,Combis and labellers.

Suitable for products of high and lowacidity

Suitable for products of high and lowacidity

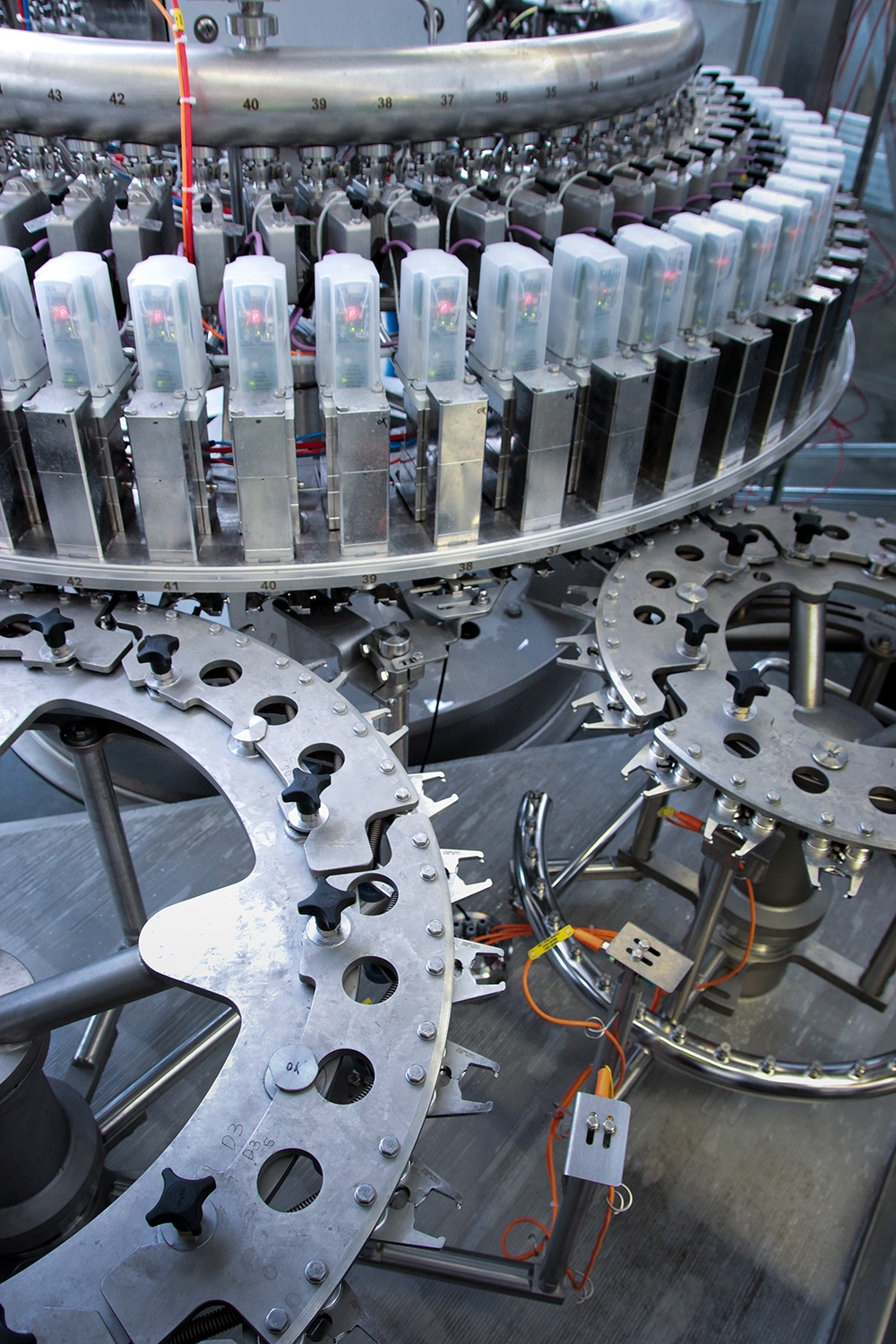

Based on Sidel's experience of sensitive products and existinghotfill technologies, the new Sidel Matrix hot filler has beendeveloped to meet these high safety and quality productionstandards for any kind of drink - of high or low acidity - to bebottled in PET containers in sizes from 200 ml to 2 litres. It is suitable for still products, such as teas, isotonicbeverages, juices and nectars. Equipped with Sidel's'Integrated Slurry Dosing' (ISD), it also handles products withpulps or fruit pieces, sacs or fibres for products like pulpyjuices, flavoured waters with fruit pieces, even Chinese Aloe Veraor coconut-based drinks. Having electronic filling valves eachequipped with individual flow meters, it is extremely accurate indispensing the appropriate filling volumes, while minimisingproduct wastage. The new hotfill machine is also capable ofoperating at production rates ranging from 6,000 to 60,000 bottlesper hour.

Robust and modular

Robust and modular

The Sidel Matrix hot filler offers great end-productversatility, managing a broad range of products with or withoutpieces. In straightforward block-rinser configuration, it managesstill beverages, with a simple grid valve. It can also handleproducts with small pulps and fibres up to 1 x 10 mm, with theoption of a plunger valve. It is also available for productswith pieces measuring up to 10 mm3, using a volumetricbits dosing turret.Of course, any of these configurations can beutilised as the 'filling' module of a fully integrated'blow-fill-cap' solution within a Sidel Combi set-up.

All components of the Sidel Matrix hot filler that come intocontact with the product are made from stainless steel and sizedfor a robust and durable design to give a long and productiveworking life. The fillers can readily be adapted to meet customers'changing needs and the system's upgradeable platform will enablecustomers to take advantage of technical developments that areintroduced in the future.

Hygienic design for product quality andintegrity

Hygienic design for product quality andintegrity

Throughout the entire packaging process, Sidel's Matrix hotfiller ensures complete product safety through hygienic design andcontactless filling valves. The product never comes into contactwith the ambient air and at no point during the production processis any bottle in contact with the filling valve, therefore reducingthe risk of cross contamination.

The filling environment of the Sidel Matrix hot filler can betailored according to the level of hygiene required by the productbeing bottled, with various alternatives being available: an openenclosure with the option of a roof with an air filtration unit anda reduced enclosure. In the reduced enclosure, the volume ofthe filling area has been lowered by 72% compared to the standardconfiguration. Requiring fewer chemicals to clean the space,this offers greater hygiene and less filtered air treats thefilling area. It uses an automatic cleaning system for whichall effluents are drained into one single point, through collectingtrays located around the base and the carousel.

Accurate filling

Accurate filling

Throughout the filling process, it is possible to control theflow rate from the tank to the filling valve without stressing theproduct being bottled. Any turbulence created by changing theflow rate remains within the tank, which acts as a buffer from theincoming product. This does not affect distribution anddelivers a constant pressure on the filling valve, ensuring highaccuracy in the process whilst the dual-speed filling avoids thegeneration of any foam. The bottle and filling valve are bothfixed during filling, to avoid any splashing and subsequent productwastage.

When the slurry dosing (ISD) is integrated, the systemundertakes a two-phase process: the first phase delivers the slurry(or particles) into the bottle, and the second fills the liquidjuice. The slurry-dosing turret is also equipped withcontactless valves. No parts enter the bottle, so once again,hygienic filling is ensured. The conic design of the valvefor the volumetric doser avoids product leakage and waste.

This dual-stream dosing by pistons ensures a constant andaccurate delivery of pulp or slurry. Particle concentrationcan be adjusted from 20ml to 300ml, depending on the recipe andsize of format being bottled, with a tolerance of plus or minus10%. With less than 10% of particles being damaged, the SidelMatrix™ hot filler therefore ensures beverage quality, maintainingthe physical integrity of the particles during processing.

Forward-looking solution backed by 40-yearsexperience

Sidel's first hot filling was into glass bottles and took placeback in 1969. The company's blow moulding, heat resistant,process expertise dates back to 1986. With over 40 years experiencein hotfill solutions, Sidel has now installed more than 900 piecesof equipment worldwide for both glass and PET, including innovativePET heat resistant (HR) packaging solutions.

Press release to download.

HD pictures to download.