02/03/2015

The patented technology ensures greater accuracy indistribution of material during the production of individualbottles, with the elimination of inconsistencies resulting inimproved quality, regardless of bottle weight.

Bottle quality affects brand perception

The blow moulding process is becoming increasingly important asthe drive for ultimate lightweighting of PET bottles within theindustry continues. Poor or irregular material distribution withinthe production of bottles can adversely affect quality throughoutthe entire process and can even lead to a total shutdown of theline. Because the appearance and handling of the bottle is whatultimately affects how any brand is perceived, Sidel is continuallystriving to create the highest quality and performance possible inPET bottles. With the new Sidel Matrix™ blower, Sidel ischallenging the conventions of production and manufacturers canrest assured that their beverage brand will consistently appear onthe shelves exactly as they intended. With the introduction ofIntelliblower, Sidel is also leading the way in blow mouldingperformance with this unique patented blowing process control andself-regulation system.

Embedded intelligence enables improvedquality

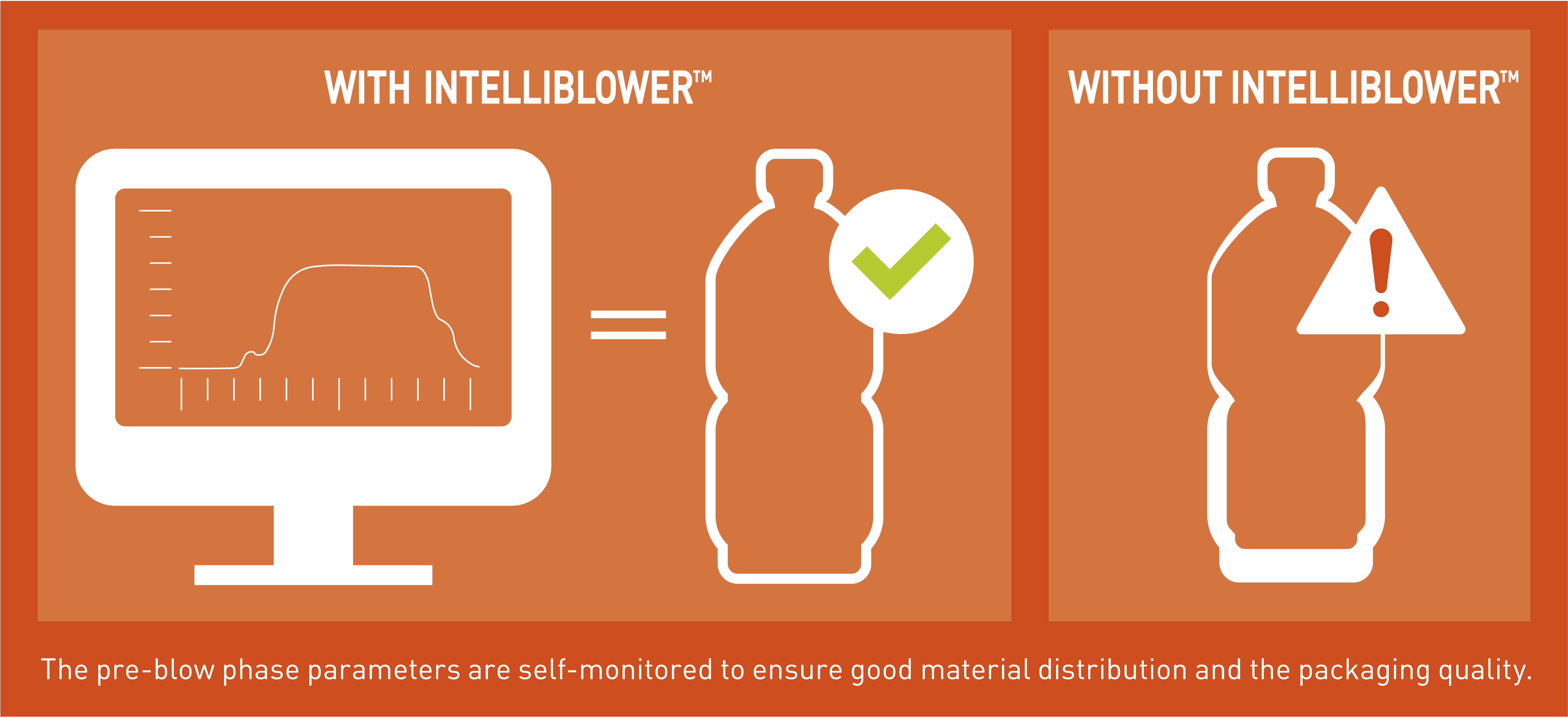

Prior to Intelliblower, qualitycontrol for PET bottle blowing involved frequent sampling andlaboratory testing of bottles. This was then followed by manualadjustments to the process. The procedure is lengthy andconsiderably reduces line efficiency. More importantly though, itdoes not completely remove the possibility that a number of bottlesmay still be produced outside accepted tolerances. By controllingparameters of the pre-blow phase that strongly impact finalmaterial distribution instead of simply focusing on regulation ofheating, the Sidel Intelliblower uses PET material optimally andcost efficiently. It is therefore able to have a higher impact onproduction uniformity and packaging quality, irrespective of theweight of the bottle being produced.

Prior to Intelliblower, qualitycontrol for PET bottle blowing involved frequent sampling andlaboratory testing of bottles. This was then followed by manualadjustments to the process. The procedure is lengthy andconsiderably reduces line efficiency. More importantly though, itdoes not completely remove the possibility that a number of bottlesmay still be produced outside accepted tolerances. By controllingparameters of the pre-blow phase that strongly impact finalmaterial distribution instead of simply focusing on regulation ofheating, the Sidel Intelliblower uses PET material optimally andcost efficiently. It is therefore able to have a higher impact onproduction uniformity and packaging quality, irrespective of theweight of the bottle being produced.

Self-regulating, the Intelliblower system automatically detectsand corrects process deviations on the shape of each bottle beingblown, adapting to maintain an even material distribution with onlythe most minor variations. This ensures that every milligram of PETis correctly allocated. With control of this level combined withthe packaging expertise and process capability of the SidelIntelliblower, waste is reduced and excellent PET lightweightingpotential is possible, even with recycled material (R-PET).

A very responsive process correction

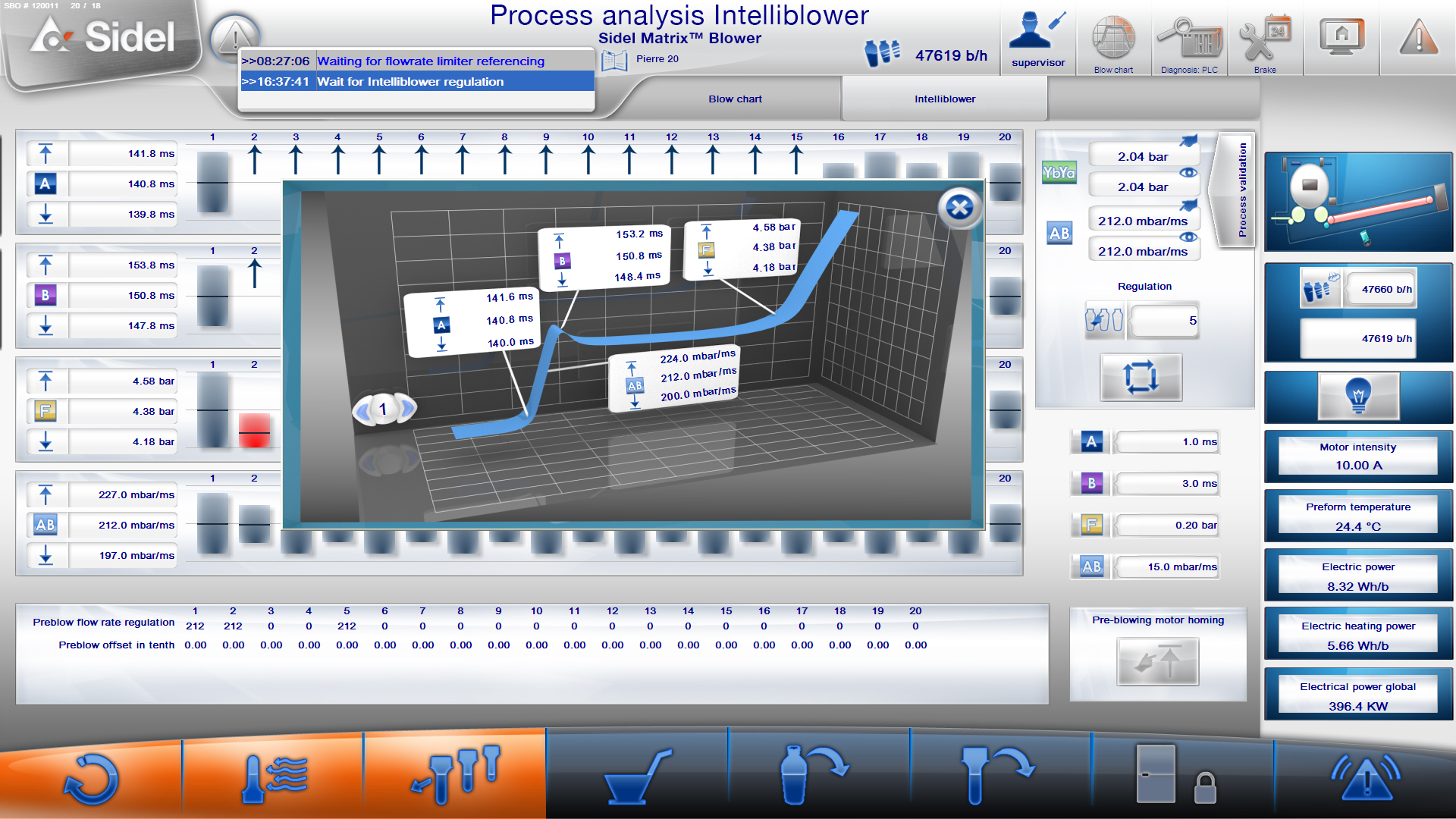

Inconsistencies of material distribution within the bottles areusually caused through incorrect blowing pressures of individualblowing stations, by inaccurate component calibration or throughwear and tear of mechanical components. The self-regulation ofSidel Intelliblower avoids these deviations by analysing andcontrolling the blowing curve on each individual bottle. Thisproduces accurate and consistent distribution with a closed loop oneach blowing curve and adjustment of critical points during thepre-blow phase. This process regulation is managed in aresponsive way by using decentralised and more responsiveautomation that allows faster and better exchange of information.As a result, only five consecutive bottles are produced at ablowing station before the necessary correction is validated. Thisself-regulation means far less sampling, testing and adjusting forproducers, along with increased bottle quality.

Simple self-regulation of the blowing curve

Sidel Intelliblower is designed to beuser-friendly. Its operation is based on continuous and automaticprocess regulation without the need for any manual intervention.This regulation is applied in three areas: pre-blow start, pre-blowflow and pressure. The line operator defines the blowing processthat matches the technical specifications of the desired bottleshape and these parameters are used to define the pre-blowreference curve. Then the real blowing curve is systematicallyself-monitored at each blowing station during actual production ofthe bottles. If blowing deviates from the reference curve, acorrection is automatically implemented. Finally, referenced andreal blowing process phases are aligned in terms of pre-blow timing(start and duration) and the pressure at all the blowing stations.This continuous regulation is performed on every bottle to ensureeach one consistently meets the necessary specification. WithSidel's Intelliblower, the standard deviation of materialdistribution between different blowing stations can be halved whencompared to a machine without self-regulation.

Sidel Intelliblower is designed to beuser-friendly. Its operation is based on continuous and automaticprocess regulation without the need for any manual intervention.This regulation is applied in three areas: pre-blow start, pre-blowflow and pressure. The line operator defines the blowing processthat matches the technical specifications of the desired bottleshape and these parameters are used to define the pre-blowreference curve. Then the real blowing curve is systematicallyself-monitored at each blowing station during actual production ofthe bottles. If blowing deviates from the reference curve, acorrection is automatically implemented. Finally, referenced andreal blowing process phases are aligned in terms of pre-blow timing(start and duration) and the pressure at all the blowing stations.This continuous regulation is performed on every bottle to ensureeach one consistently meets the necessary specification. WithSidel's Intelliblower, the standard deviation of materialdistribution between different blowing stations can be halved whencompared to a machine without self-regulation.

A perfect way to anticipate maintenance

Through the Human Machine Interface (HMI) of the Sidel Matrixblower, process values of individual blowing stations are recorded,along with dedicated graphs. This gives operators a comprehensiveoverall picture of the process performance. It also alerts them toany potential inconsistencies, indicating those stations where anybottles are being blown outside accepted tolerances. They aretherefore able to easily identify malfunctioning stations and planany necessary maintenance in order to minimise impact onproduction. Even if maintenance is deemed necessary,production generally still remains viable. As a whole, the SidelMatrix blower is reducing the amount of maintenance and manualoperations required, while lowering labour and control costssignificantly.

With Sidel Intelliblower, beverage producers are able to enjoyimproved bottle quality due to higher blow moulding performancealong with an increased insight into the operation of theirproduction equipment. Put even more simply, they will benefit fromgreater package consistency and subsequently, better brandvalue.

Sidel is constantly striving to challenge the conventions of PETproduction and rise above the expectations of beverage producers.For more information on Sidel Matrix blowers, please visit sidel.com/matrix-blower.