14/07/2016

All are important factors in helping beveragemanufacturers to convert market opportunity into profitable,long-term success.

"There's no doubt that the CSD market is changing at anexceptional pace," says Stefano Baini, Product Manager for RegularFilling at Sidel. "However, with CSDs remaining one of the world'smost valuable soft drink categories - exceeded in quantity salesonly by bottled water - these changes are creating room forgrowth."

Opportunities in both emerging and establishedmarkets

In developed and emerging markets, there is a noticeabledifference in the challenges that beverage producers face - yetboth can offer opportunities for growth to the proactive CSDbottler.

In developed markets, the industry is seeing a shift to'healthier' carbonated soft drinks. In 2015, 25% of globallaunches of new carbonated soft drinks carried some kind of'natural' claim[1], which highlights the increasing role thatsuch beverages are playing in the CSD market. This trendtowards 'better-for-you' innovations shows no signs of slowing,with market analysts suggesting that they are likely to beimportant in the future prospects of CSDs in all thefastest-growing markets[2].

Production flexibility is key tosuccess

In the global CSD market, commercial growth requires consumerunderstanding supported by flexible production technology. Infact, new technology continues to open up opportunities and helpsmanufacturers create the new products that consumers want whilemeeting their own needs for greater sustainability.

With equipment that can easily and quickly be converted toaccommodate different stock-keeping units (SKUs), manufacturers canenjoy the flexibility to adapt to different market needs. Modular lines that can be easily converted to new beverage recipesand container formats are a quick and cost-effective way to get newproducts onto the supermarket shelves.

Over 85 years' experience in bottle filling

With a history in the filling of beverages dating back to the1930s, Sidel now provides solutions for filling all kinds ofbeverages and liquids, including CSDs. A comprehensive rangeof beverage filling solutions offers performance, product quality,flexibility, hygienic design, food safety, minimal maintenance,automatic changeovers and quicker cleaning - together with lowesttotal cost of ownership (TCO).

Choosing the right filling technology is essentialto producing a consistently high quality beverage. From thecompany's different solutions, Sidel helps producers to choose thefilling technology best suited to their needs. The decisiontakes into account many factors, including the producer's hygienicrequirements, their consumption of utilities, the skill levels oftheir operators and the ambient production and transportationconditions.

Choosing the right filling technology is essentialto producing a consistently high quality beverage. From thecompany's different solutions, Sidel helps producers to choose thefilling technology best suited to their needs. The decisiontakes into account many factors, including the producer's hygienicrequirements, their consumption of utilities, the skill levels oftheir operators and the ambient production and transportationconditions.

Alongside the need for the right technology is the means toidentify how the beverage will perform within the bottle. Sidel has two laboratories for filling and aseptic microbiologicalcontamination analysis in Parma, Italy - and two laboratories forliquid-packaging and aseptic analysis in Octeville, France, tosupport beverage producers around the world. In order todetermine the most suitable size, shape, closure and PET resin touse for packaging, as well as identifying how it behaves during thefilling process, Sidel experts test the recipe, viscosity, PH leveland carbonations of the product being bottled over a period oftime.

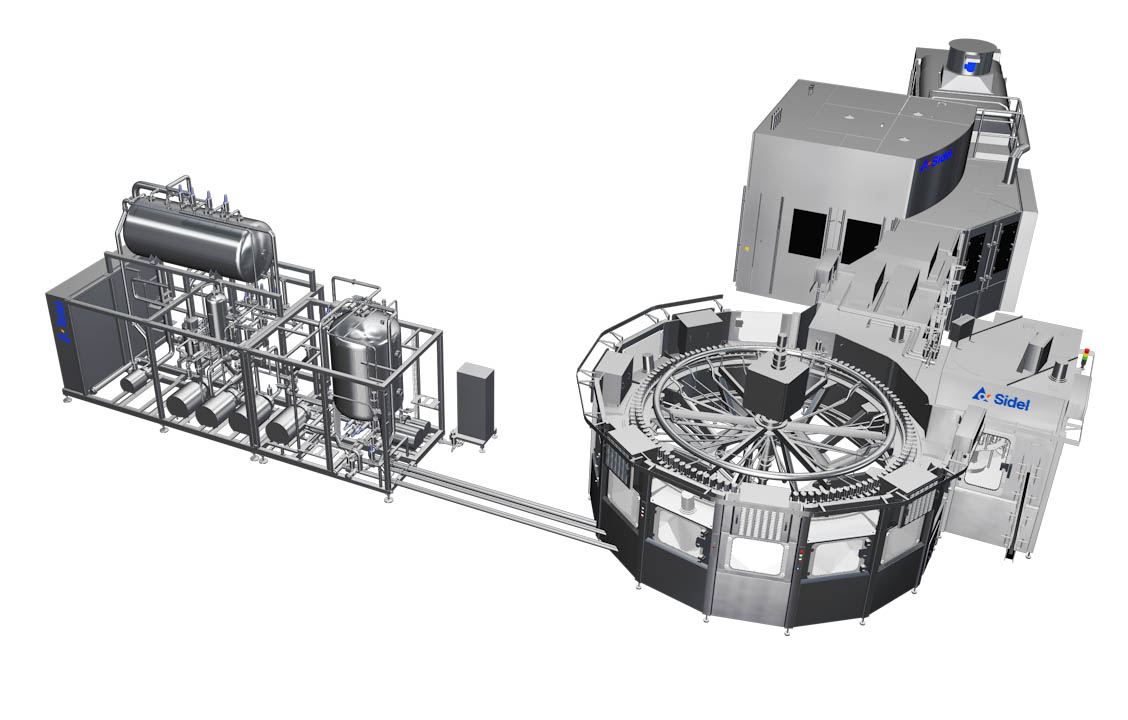

Sidel Matrix Filler SF300 FM for precision filling ofstill and carbonated soft drinks

Robust and reliable with a sturdy structure, the Sidel Matrix™Filler SF300 FM is suitable for accurately filling still andcarbonated drinks, offering quick changeovers without beverageloss. The latest generation of filling machine from Sidel, itutilises modules with proven reliability and delivers up to 98%efficiency, filling PET bottles with precision at rates of up to80,000 bottles per hour (bph). It reduces the use of carbondioxide gas (CO2) and, using servomotors, it alsoreduces the consumption of electrical power. In addition, itoffers strict hygiene, fully automatic changeovers performed viaHMI (Human Machine Interface), optimum uptime and highestproductivity. With magnetic or mass flow meter control, the SidelMatrix Filler SF300 FM ensures there are no limits in filling,whatever the beverage and regardless of conductivity level,providing the most accurate precision, avoiding any waste.

Smooth, safe handling avoids stress, reduces turbulence andprevents the unnecessary foaming of the carbonated beverages. This eliminates spillages and waste of the beverage beingfilled. Quick and easy to clean, the external beverage tankfacilitates fast changeovers, saving even more time and reducingcosts for the CSD producer. The Sidel Matrix Filler SF300 FMrequires 30% less downtime for maintenance than comparablefillers.

Minimal product loss and reduced CO2consumption

Sidel's compact, hygienic and safer Blendfill solution has afully integrated filler and mixer to combine both processes in onesystem in order to minimise product loss when switching betweenbeverages. A simplified solution with fewer components andfunctions, it has only one tank, utilising the Sidel Matrix MixerSM500 beverage tank as a shared tank with the filler, avoidingredundant pressure and level control functions. This reducesconsumption of CO2 as well as the equipment footprint.It ensures automatic and fast recipe changes by using a singleHMI.

Complete solutions for CSD built for today andtomorrow

With consumer preferences changing in today's carbonated softdrinks market, product diversity is more important than ever forproducers. Sidel's latest generation of equipment, Sidel Matrix,currently provides three times more configurations, enablingproducers to package various carbonates, types of beverages andrecipes in varying formats up to 3.5 litres. Finding theoptimum solution for filling carbonated soft drinks goes beyond theinitial choice of filling equipment; the best solution requires aflexible approach to the complete line. Technologicaladvances are making PET bottling lines more sophisticated and lineautomation is expanding performance possibilities.

"Starting with the packaging itself, Sidel experts will helpdesign and manufacture a complete CSD PET bottling line solution,right from the beginning, working closely with producers every stepof the way. Sidel is able to fill containers with precision andefficiency while handling the products smoothly and gently. Regardless of the beverage type, we offer robust and reliablefilling solutions, hygienically designed and based on extensiveknow-how and experience," concludes Stefano Baini.