09/06/2016

"As a result of the ever-changing market, beverageproducers are generally now taking a more holistic approach to theinstallation of new bottling lines," explains Mr. Clive Smith,Executive Vice President of Sales & Marketing at Sidel. "Here at Sidel, we genuinely believe it is the key to maintainingoptimum performance and attaining the most cost-effectiveoperational life over the longer term."

Much more than a simple choice of equipment

Sidel believes that finding the optimum solution for anybottling line goes beyond any simple choice of equipment. Whether producers are bottling water at high speed or packagingdairy products with high sensitivity, it is always best that theyconsider the specific production needs of any line from the verybeginning.

By partnering with Sidel from the start and collaborating atevery step of the installation, beverage producers can boost speedand hygiene with Sidel water lines, ensure flexibility and quickchangeovers with Sidel carbonated soft drinks lines and increasetheir packaging freedom with Sidel hot fill lines. With thecompany's aseptic wet lines, producers can improve bottlelightweighting at the same time as reducing the consumption ofresources. With its dry, low-speed aseptic lines, they canreduce their footprint and ensure a faster ramp-up and, with thehigh-speed version of the same line, can maximise productivity andflexibility.

The best packaging development

Working with Sidel, beverage producers gain accessto a thorough understanding of the entire supply chain, fromcurrent market trends and changing consumer tastes to thechallenges of beverage distribution and local regulations allaround the world. Sidel's dedicated in-house packaginglaboratories and technical know-how can help industrialise a bottlethat is lightweight, flexible and durable.

Working with Sidel, beverage producers gain accessto a thorough understanding of the entire supply chain, fromcurrent market trends and changing consumer tastes to thechallenges of beverage distribution and local regulations allaround the world. Sidel's dedicated in-house packaginglaboratories and technical know-how can help industrialise a bottlethat is lightweight, flexible and durable.

The liquid package interaction analysis determines the mostsuitable packaging for the customer. This includes analysingthe bottle neck and cap where significant performance improvements,as well as cost savings, can be realised through factors such aslightweighting and the tightness of the cap. Sidel's virtualbottle modelling and finite element analysis can assess itsstability, rigidity and quality. Full feasibility performancetests can then validate its strength and ensure it performs in thereal world.

Equipment for optimised uptime

Sidel can help any producer choose the right equipment for thespecific needs of any beverage. Every step of the way,Sidel's knowledge of all the processes involved in the PET bottlingprocess, from blowing through to palletising, and its reliable andhigh-quality, modular equipment, ensure that lines can be flexiblyadapted to get the most out of the producer's investment. Sidel machines offer flexibility, quick and automatic changeoverswith fast module replacement and upgrades. Along withlong-term and reliable uptime and short cleaning times, this allhelps producers achieve optimum productivity. Sidel machineryis also designed to maximise sustainability by reducing overallrunning costs and use of resources. While ensuring highbottle quality, Sidel blowers save both air and energy. Fillers avoid spillage and waste, carry out automaticbottle/beverage changeovers and minimise the use of electricity andcleaning agents. Sidel labellers cut the amount of energy andmaterials consumed and the time needed for maintenance. Packers save on energy and materials - and automatically carry outthe changeover of both material and pack configuration. Sidelpalletisers make transportation more effective, and production moreefficient.

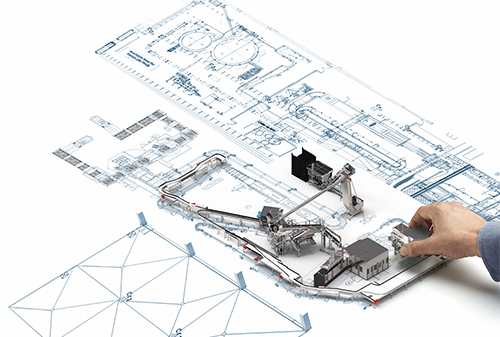

Optimal line design

Sidel works with line designs at any stage ofdevelopment, preferring to work closely with customers from thevery start. Whether it is a new greenfield project, therenovation of an existing facility or the modernisation of anageing line, Sidel is able to create layouts of complete PETbottling lines to suit any context or environment.

Sidel works with line designs at any stage ofdevelopment, preferring to work closely with customers from thevery start. Whether it is a new greenfield project, therenovation of an existing facility or the modernisation of anageing line, Sidel is able to create layouts of complete PETbottling lines to suit any context or environment.

The company's dedicated project management and engineering teamsassist in the design of the line, optimising the footprint whileminimising the use of raw materials, energy and otherresources. The selection of the most appropriatetechnologies, the choice of the most suitable size of chosenequipment and accumulations, the defining of line controls andautomation, the actual footprint of the line, the management of rawmaterials and other resources - these are all essential engineeringdecisions that Sidel consider to ensure the line fully meets allthe requirements of any producer.

From delivery to ramp-up in record time

To ensure the new line is delivered, installed and undergoes aquick ramp-up for safe, full, commercial production, Sidelthoroughly plans and manages the entire process. Thecompany's project and site management teams communicate withsub-suppliers, following up all communication and queries, speedilyand efficiently - keeping a close watch on all deadlines to ensuresmooth delivery. During manufacturing and for these fastinstallations and ramp-ups, Sidel takes a 'lean approach',delivering high-quality, reliable equipment. Extensive testsare performed in-house on pre-assembled equipment to reduceinstallation time and to ensure full commercial production isachieved quickly and safely.

Sidel's structured smart data

Once a line is up and running, Sidel's real-time data solutionskeep productivity at its best. Constant monitoring providesdata-driven assessments for full, real-time traceability anddetailed insights. Managers can view comparisons and processinformation for a complete efficiency overview. Operators canaccess the performance details to monitor line flow and maintainstability by spotting bottlenecks, highlighting inefficiencies andidentifying areas for improvement and cost optimisation. Efficiency targets are therefore maintained, costs are kept undercontrol and the potential to improve performance is increased.

Maintaining and improving productivity, efficiency andperformance

When Sidel has designed, built and installed a PET bottlingproduction line, the Sidel Services™ team is then able to offerproducers a dedicated, tailored portfolio that can increase thevalue of beverage production for long-term success.

A team of experts will monitor performance, offering 24/7support and on-site diagnostic visits, pre-planning downtime andproviding fast corrective maintenance should a breakdownoccur. Line conversions, along with new original moulds fromSidel, can deliver greater uptime, reduced costs and increasedproduction flexibility as consumer demands change. Thecompany is currently offering over 500 options and upgrades toenable any line to benefit from new technologies as they becomeavailable to boost its performance. Sidel's expert trainingin new methodologies and procedures can also help improveproduction and can take place on-site, online or at any SidelTraining Centre.

"To bring your beverage idea from concept to industrial reality,the best solution goes beyond the equipment and starts at the verybeginning," concludes Sidel's Clive Smith, "with technical know-howand packaging expertise that comes from a full solution partnersuch as Sidel."