17/01/2017

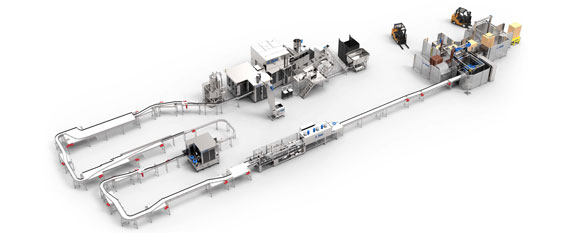

By taking a holistic view of the production cycle, a fully connected line can be optimised through a combination of lightweight packaging, great efficiency and hygiene, always keeping the total cost of ownership (TCO) as low as possible.

Water is a precious commodity. Increasing urbanisation in developing countries - and the resulting need for regular access to drinkable water, and the move away from sugary beverages in more mature markets has driven a growth in demand for bottled water around the world. Global sales climbed in volume by 6.7% between 2014 and 2015 to reach 193 billion litres with still water accounting for 86% of this total[1]. The material of choice in this growing market is PET, covering 86% of all projected bottled water packaging sales in 2016.[2]

With more than 40 years' experience with complete line solutions and the world's largest installed base of Combi integrated blow-fill-cap systems, Sidel has helped producers to reach and exceed their targets, time after time.

"Smarter solutions and innovations are essential to meeting the needs of the rapidly expanding and ever-changing bottled water market. A complete line approach recognises the roles that lightweight and safe packaging, top quality equipment, optimised line design, smart automation and ongoing services all have to play in meeting the market challenges. It offers producers full control and transparency throughout the bottling process," says Simone Pisani, Category Marketing Director Water at Sidel.

Value adding innovations by in-house experts

With the aim of improving bottle strength and performance while reducing costs and ensuring the brand stands out on the shelves, Sidel scientists and in-house packaging designers work on more than 250,000 new bottle concepts every year. At 5 packaging centres and 4 in-house R&D laboratories around the world, they help producers to qualify and industrialise specific packaging solutions that satisfy consumer needs and help to differentiate products on the shelf. Creating and evaluating bottle samples and performing many different laboratory tests, they take care of the safety and quality of customers' beverages, as well as of the best product's performance throughout the supply chain, and enhance their value proposition to consumers.

One of Sidel's many recent innovations within bottled water production is the development of the Sidel Rightweight™ bottle. This design reduces bottle weight and energy consumption during production, while improving the container's performance across the entire supply chain and delivering a superior consumer experience. The resulting 0.5 litre bottle weighs 35% less than the average commercial alternative, yet achieves 32% greater top-load performance than the lightest commercial bottle, resulting in cost savings of up to EUR 1.74 million per year[3].

One of Sidel's many recent innovations within bottled water production is the development of the Sidel Rightweight™ bottle. This design reduces bottle weight and energy consumption during production, while improving the container's performance across the entire supply chain and delivering a superior consumer experience. The resulting 0.5 litre bottle weighs 35% less than the average commercial alternative, yet achieves 32% greater top-load performance than the lightest commercial bottle, resulting in cost savings of up to EUR 1.74 million per year[3].

Sidel has also developed a new PET base for still water. Sidel StarLite™ has a unique shape that significantly increases base resistance and stability. Through this solution - which can even be applied to existing lines - overall package weight is lowered without affecting beverage quality.

With StarLite, bottles for sparkling water can also benefit from improved protection against stress-cracking, a similar reduction in base-weight and improved bottle performance.

Compact and reliable water solution

Sidel's fully integrated, hygienic and innovative solutions - gained from extensive cooperation with leading water brands - help producers to optimise uptime and operating costs. The portfolio includes a range of modular equipment and components, able to increase line efficiency and speed while ensuring food safety and hygiene.

The Sidel Matrix™ Combi, offering blowing, filling and capping processes in one machine, optimises the production line layout with a smaller footprint. It efficiently combines the benefits of the Sidel Matrix blower with those of the SF100 FM filler for still water or the SF300 FM filler for sparkling water. By eliminating intermediate conveyors and reducing the volume of the production environment to be kept under control, hygiene and food safety are improved. Additionally, the Combi offers faster changeovers with savings in power consumption, labour, raw materials, maintenance time and spare parts, lowering operating costs by up to 12%. More importantly, Combi systems offer high performance with efficiency levels up to 4% better than standalone machines.

Integration of carbonating and filling processes

The Sidel Matrix Combi also features Sidel's Blendfill configuration, combining carbonator and filler in a single system for top quality sparkling water. Utilising the Sidel Matrix Carbonator SM100 beverage tank as a shared tank with the filler, the configuration avoids redundant pressure and level control functions, while reducing consumption of CO2 as well as the footprint of the equipment.

Optimised cleaning while saving resources

Smart cleaning technology also reduces energy and chemical use by up to 70%. Sidel's compact Integrated Cleaning System (ICS) is a simple and hygienically designed solution that, combined with the filler skid, ensures quick preparation of cleaning agents so that all equipment parts that come into contact with the water are effectively cleaned.

Reduced waste for improved safety and hygiene

As many factors can affect the amount of product splashing within a filling process - speed, bottle shape, neck dimensions, fill-level to name but a few - Sidel uses all its expertise and in-house simulation tests to help producers overtake the issue. Virtual modelling and real-life testing help avoid any splashing and maintain safety of the filling environment, especially at very high speeds.

Giving the final package a memorable look

Labelling is an essential factor to ensuring a product stands out on supermarket shelves. Roll-fed technology uses plastic labels, which have physical and functional qualities making them very attractive to consumers and beneficial for beverages producers. The Sidel Matrix SL70 efficient roll-fed labelling station delivers precise and controlled handling and application for containers of any shape. It is capable of outputs of up to 60,000 bottles per hour. With shorter changeover times for containers of different shapes and dimensions, this ergonomic and reliable system maximises operator safety, uptime and productivity by reducing maintenance time by 40%, while enhancing sustainability as it uses up to 40% less power.

Flexible pack configurations, quick changeovers and optimised transportation

The secondary packaging - the finished pack that the consumer sees at the point of sale - represents a strong opportunity to reinforce brand recognition and so needs to be appealing, durable and functional to catch attention. Carrying the labelled bottles onto the secondary packaging process, Sidel's smart conveyors can be automatically adjusted to handle different formats. Gently feeding the bottles to maintain consistency and quality, the packers also protect them from elements such as weather, pressure and temperature change. To minimise overall costs, they also optimise the use of heat, glue, cartons and film. All Sidel's packers ensure quick changeovers for flexible handling of multiple stock keeping units (SKUs).

The secondary packaging - the finished pack that the consumer sees at the point of sale - represents a strong opportunity to reinforce brand recognition and so needs to be appealing, durable and functional to catch attention. Carrying the labelled bottles onto the secondary packaging process, Sidel's smart conveyors can be automatically adjusted to handle different formats. Gently feeding the bottles to maintain consistency and quality, the packers also protect them from elements such as weather, pressure and temperature change. To minimise overall costs, they also optimise the use of heat, glue, cartons and film. All Sidel's packers ensure quick changeovers for flexible handling of multiple stock keeping units (SKUs).

Sidel palletisers allow easy changeovers in layer formation to organise the right number of single bottles onto - for example - trays, dollies or packs onto pallets. In this way they achieve smart pallet patterns of various sizes and formats of bottles, in order to optimise efficiency during transportation and storage.

Maximum uptime and minimum TCO

Once a line is up and running, Sidel Services™ offers a tailored portfolio to help maintain, regain and even improve performance throughout the equipment's lifetime. From customised maintenance, through to line improvement, to spare parts and logistics services, the company combines customer proximity with global experience to shorten lead times and improve customers' efficiency.

However, it is difficult to improve what is not being measured. The market is looking for systems with "built-in intelligence" capable of translating raw data into actionable information. Sidel's Efficiency Improvement Tool (EIT™) handles production issues to meet ongoing challenges and also anticipates them through trends and forecasts based on historical and multi-plant analysis.

"By taking a global view of the Overall Equipment Effectiveness (OEE) and the entire working life of a production line, as new technologies and solutions are developed, Sidel offers existing line owners options and upgrades, line conversion and training services to ensure that installed equipment does not get left behind, while strengthening operators' skills. In this way the company is always working to help producers optimise operating costs and reach the lowest possible TCO" adds Simone Pisani.

[1] Mintel - Water Global Annual Review

[2] Euromonitor International (2016)

[3] Calculation based on a Sidel Matrix blower with 20 cavities blowing at 2,250 bottles per hour and 6,000 hours of production per year, with a PET cost of Euro 1,600 per ton

Download high quality pictures