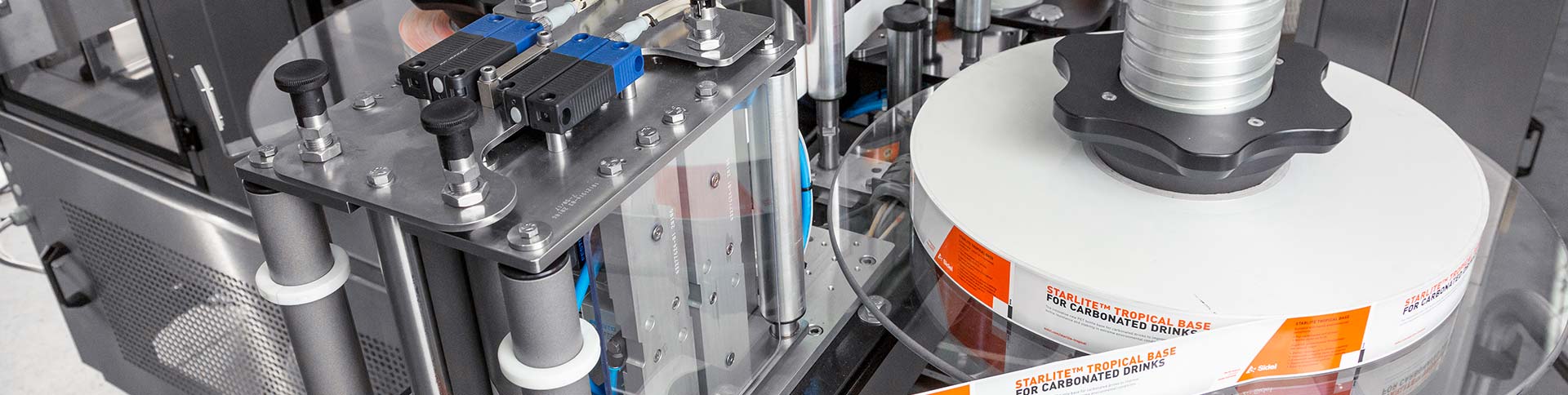

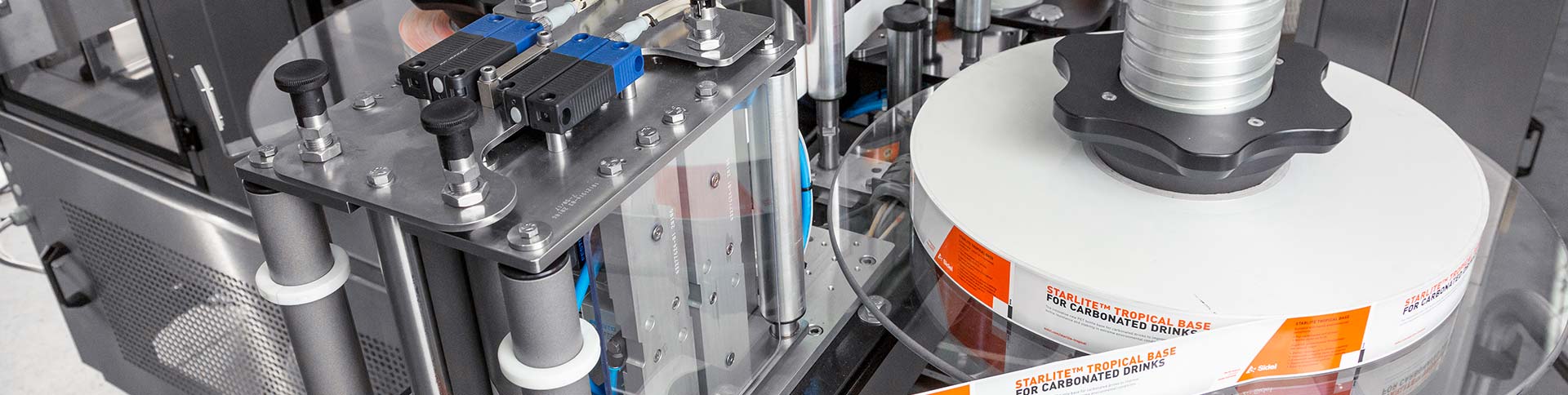

Labelling PET containers, especially for soft drinks and water, primarily uses wraparound roll-fed technology, applying either paper or plastic labels with hot glue. Sidel Roll-fed labelling solutions deliver the flexibility needed to match all your needs.

The success of roll-fed technology lies partly in the plastic label, which has physical and practical qualities that make it very attractive to consumers and beneficial for beverages producers. In addition to a high gloss finish, roll-fed labels are waterproof and consequently less likely to be affected by adverse storage conditions. Furthermore, they are able to meet a fast-growing market trend that calls for efficient, high-speed machines able to handle lightweight containers with extremely thin labels.

|

Max. Speed (bph)

| Bottle diameter (mm) |

Machine model

|

Carousel diameter (mm)

|

Heads

|

Pitch (mm)

| |

|---|---|---|---|---|---|---|

| Min | Max | |||||

| 34,000 | 53 | 110 | RQ F15E 18T | 720 | 18 | 126 |

| Machine Model | Label length (mm) | Label height (mm) | Label material | Label thickness | ||

|---|---|---|---|---|---|---|

| RQ F15E 18T | Min | Max | Min | Max |

OPP white OPP transp. Paper |

25 - 50 µm |

| 177 | 355 | 30 | 170 | |||

The Sidel RollQUATTRO Evo's unique linear station design and ergonomic structure means that operators can control all labelling processes easily.

The Sidel RollQUATTRO Evo's module accessibility and enhanced module elements optimise cutting, glueing and label application processes.

The Sidel RollQUATTRO Evo label transfer drum, glue and cutting modules are designed to deliver high labelling accuracy and quality time after time.

Sidel RollQUATTRO Evo's unique linear station design makes access to machine modules easy and format changeovers faster.

Sidel RollQUATTRO Evo's ergonomic linear design enables the operator to control all labelling processes and allows for simpler maintenance procedures.

The Sidel RollQUATTRO Evo cuts operating costs and minimises energy consumption.

Always by your side on every step of the way to build, maintain and improve your line performance