TOP 3 BENEFITS:

PRODUCT INFORMATION

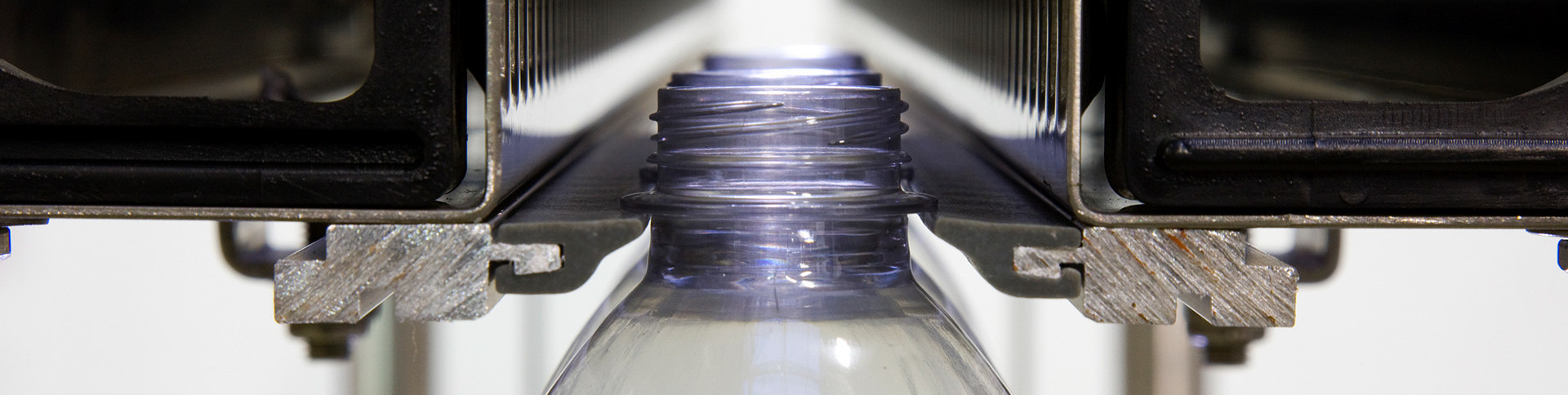

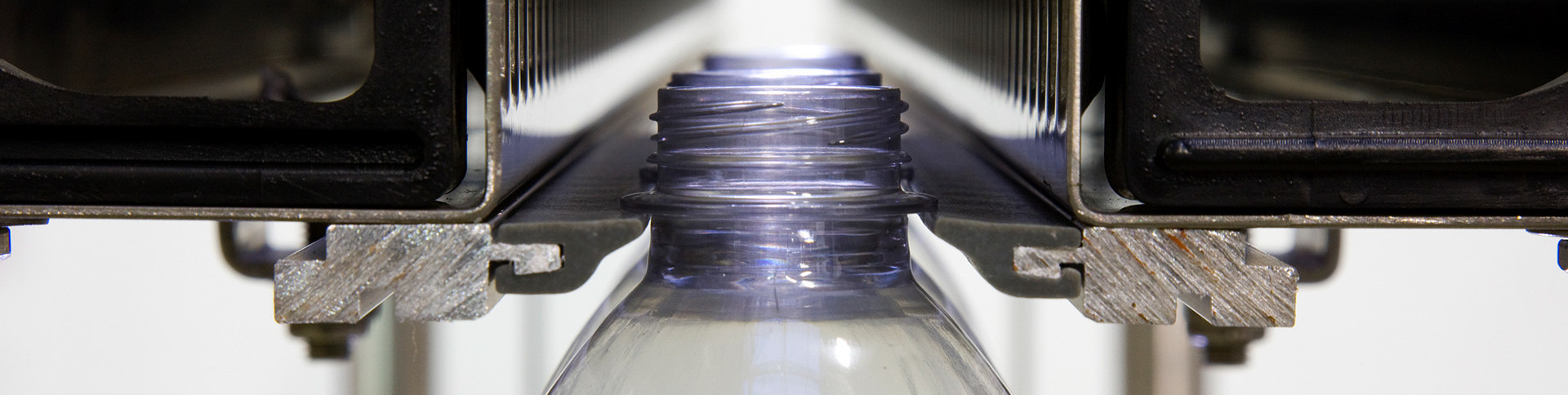

In lines that have no combi solution, empty container air conveying systems are required to transport empty PET bottles from the blower to the filler.

Sidel’s empty container air conveying systems are extremely flexible, in terms of both layout and formats and products:

Ergonomically designed for optimum cleanability, our empty container air conveying systems are fitted with a removable deck for inside cleaning. They also have a removable convex top cover with an integrated cable tray, and offer users easy clip and slide neck rail replacement.

Our systems guarantee total air purity control for product care:

Finally, our empty container air conveying systems are sustainable solutions. Higher performance and energy savings are gained through their dry lubrication for the under-neck guide, which has an improved lifespan. The lubricant is approved by food-processing standards. Our systems also benefit from a 20% decrease in drive electricity consumption by the ventilation columns. The machines’ very low friction coefficient improves reliability.

Always by your side on every step of the way to build, maintain and improve your line performance